Enameled round copper wire is one of the most durable and strong things. Next, the wire is coated to protect it against damage during manufacturing. Thanks to this special coating, the wire can be used in various environments, without requiring a lot of replacements. This can save a lot of time and money, which is critical for both manufacturers and consumers.

Anyhow, this type of wire has a lot of energy transfer efficiency. This means that copper is a very highly conducted material with the ability to carry electrical energy at a very high-speed rate. The enameled coating also prevents energy from being lost or wasted, which allows more energy to travel further distances. That's an important efficiency for many things we use electricity to make work.

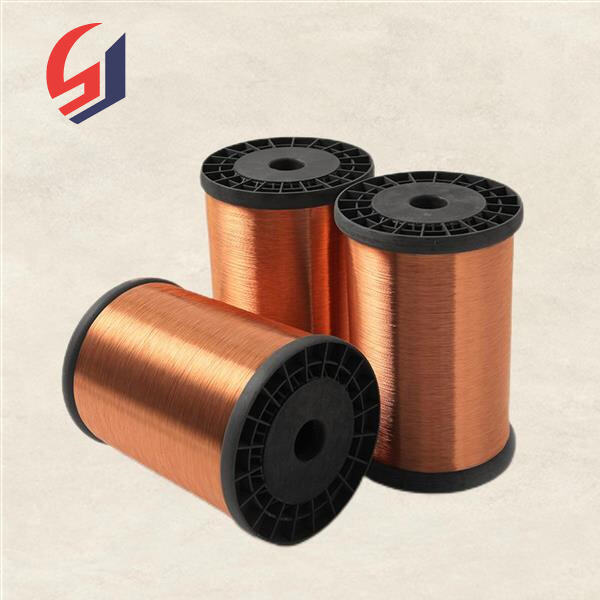

Enameled round copper wire is made of copper that has been round and is found in various sizes with different coatings on them. It’s effective for small electronic devices, such as phones and tablets, as well as larger systems, including power plants and industrial machinery. Since it can be used with such a wide range of applications, it is an excellent asset in many areas of technology.

In production of flat enameled copper wire, its quality is really important. Defects in the wire can not only disrupt a circuit they comprise, but also impact electrical shorts and other types of damage further down the line, as any fault in the wire can be deep-seated. Regular tests and inspections are performed throughout the manufacturing process to ensure the wire stays in optimum condition.

The enameled round copper wire for energy transfer has few primary benefits as compared to others. You see, copper is an extremely good electrical conductor. This allows it to transport electrical energy quickly and easily. The key to this process is an enameled coating on the wire that works to prevent energy loss and wastage. Thus, energy can be transferred over much longer distances, something that comes in very handy for plenty of applications.

Enameled round copper wire is used in many different forms of modern technology that we use every day, and is essential in the manufacturing of these devices. It is present in everything from smaller electronic devices, including smartphones and laptops, to big electrical systems like power plants and industrial machinery. So many devices and systems rely on enameled round copper wire that without it, they might not function well.

Enameled round copper wire is crucial to the functioning of renewable energy systems like wind turbines and solar panels. Such systems depend on high-efficiency wiring to convert energy from the sun or wind into usable electricity. This type of wiring is useful because enameled round copper wire is one of the most efficient types of wiring there is, so they are the perfect wiring for these renewable energy systems.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

Our enameled wire factory can customize the products according to customers' special requirements and also provide an extensive after-sales assistance. Diversified specifications: Our factory can produce enameled cables in a variety of specifications including wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.