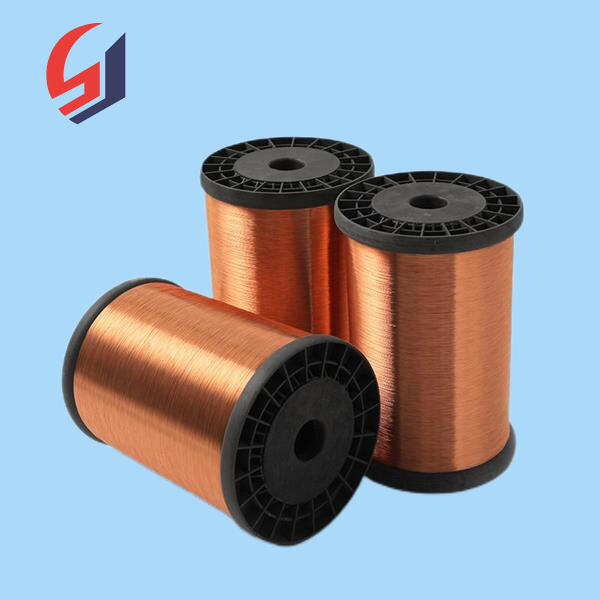

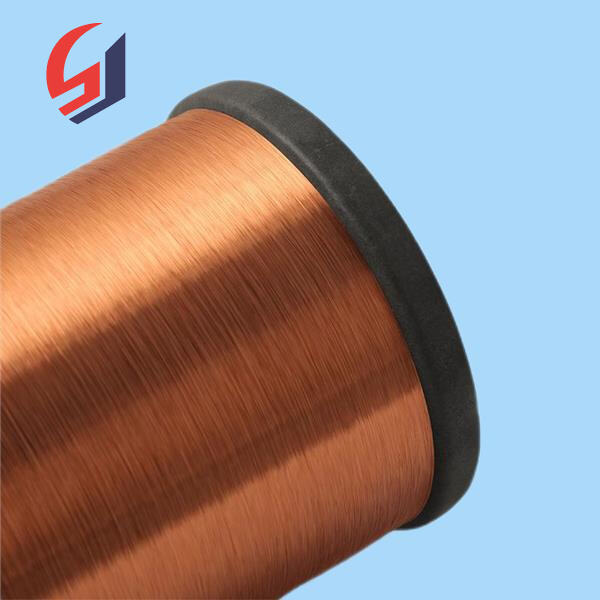

Lear about Enameled Wire GaugeWhen working with any electrical project, it is extremely important to have knowledge of the aluminum enameled wire. Enameled wire is a characteristic sort of copper wire that is secured with a meager film called protection. That insulation consists of a type of varnish that starts as a liquid, then dries and protects the wire. This protective layer prevents escaping electricity and ensures your safety when working.

Gauge is a measurement that indicates the thickness of the wire. The thickness of the wire determines how much electricity it can carry, therefore, it is critical that you select the appropriate gauge for your project. Choose the wrong gauge, and your project may not turn out the way you expect.

Selecting the correct wire gauge is important to ensure the success of your project. If the wire that you select is then too thin, it may not have enough capacity to carry electricity, and your project will likely fail. Conversely, pick a wire that is too thick and it may not fit within the area you wish to use it, which can also cause issues.

Each wire gauge has its own pros and cons. Due to their lower size, thinner wires are an excellent choice for smaller projects. But they do not carry as much electricity as thicker wires. Thicker wires move more electricity much better, but they might not fit into the tighter spaces where you need them.

Thick wires are preferred for projects that draw high current, such as motors and other power-hungry devices. Thinner wires are for projects which won't be drawing too much current (like toys and small electronics)

Choosing the right gauge of wire will have a significant impact on how well your project functions. The thickness of the wire impacts what is known as resistance. Resistance is how hard the wire will try to stop electricity from passing through it. If you have resistors, moving electrons (electricity) will be less in the drier wire; however, thicker wires have less resistance, so they can carry more electricity without getting too hot. This is critical for energy-intensive projects, as it prevents overheating.

Thinner wires offer more resistance, so they can become heated more easily when currents flow through them. For projects that draw a fair amount of electricity, this can be a very big problem, as the now too hot wire could possibly start to melt or break something.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

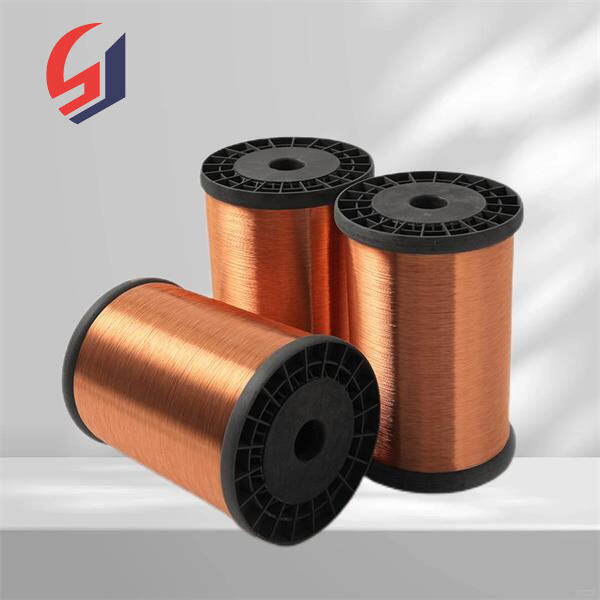

The factories we use for enameled wire assure efficient distribution of products across the globe thanks to cutting-edge production technology and rigorous quality control. We collaborate with our international logistics partners to tailor logistics solutions that are tailored to the requirements of our clients. Our global delivery network is comprised of major ports to ensure that the products reach their destinations quickly and safely. Our sales staff also provides online tracking services that keep our customers informed of the status of their shipment, improving supply chain transparency.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.