Hello, young readers! So, we are going to learn about one very special and crazy prominent term in the Electromag and Electrical world today: Super Enameled Copper Winding Wire.

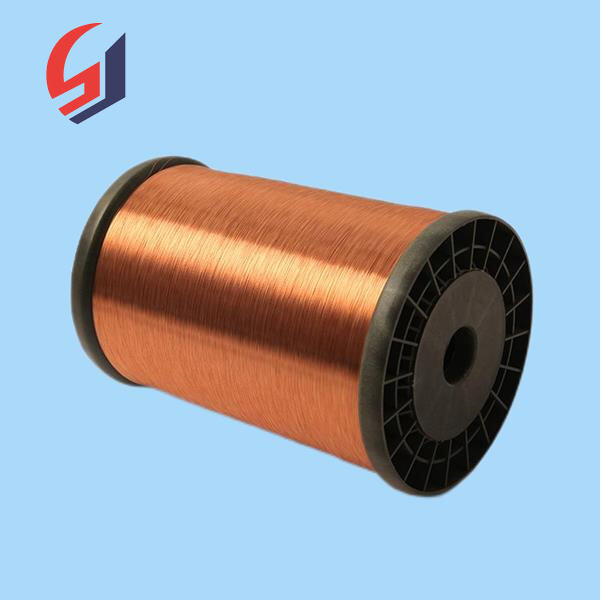

Super enameled copper winding wire is a type of wire that is produced from copper, a very conductive metal for electricity. But the cool thing about this Shenzhou Cable super enamelled aluminium wire is it is not smooth; it has plated coating. This coating is known as insulation and aids the wire in numerous ways. The insulation first makes the wire safer to use. It prevents the electricity from leaking out of the wire, which is crucial. Second, this coating helps to make the wire long-lasting. For that, it delegated with a protection, it is not easily damage. In summary, this special wire comes in quite handy for different types of electrical jobs.

This type of wire is the best option for people using electricity for a variety of reasons. First of all, it is very strong & durable. This implies that it can endure plenty of rough treatment, allowing it to endure for years without breaking. Second, it is incredibly good at transporting electricity. This means it is capable of transmitting voltage from one location to another at very low losses. When a wire is a good conductor, less electricity is wasted and energy and money are saved. Since this wire can assist many individuals in becoming quicker and more effective at their tasks.

Super enameled copper winding wire is practiced in many electrical tools and electrical devices. For instance, it is commonly used in motors, which are present in various types of machines. It is also used in transformers, which help convert the voltage of electricity so it can be used safely. Generators — the machines that generate electricity — also utilize this Shenzhou Cable super enamelled aluminium winding wires. That coating on the wire is critical because it keeps the wire from melting when it gets hot or crushed when there is a lot of pressure on it. That is why the wire is very reliable for all this important work.

Any Super Enameled Copper Winding Wire usage could potentially benefit your business significantly, whether you work on a major electrical project, or a smaller one. First of all, it can improvement the quality of the products that you make. Wire is a better and more trustable option which may strength your products and make more efficient to carry electricity. When customers are confident they can depend on your products, they are apt to return to purchase more! Second, it can save you money to use this Shenzhou Cable super enameled copper winding wire. Since the wire is better at carrying electricity, it makes your energy costs lower. You can save on electricity bills, and this all adds up, positively impacting your business and its growth.

Versatile: Due to this Shenzhou Cable super enamelled copper wire all electrical tool and device can be used easily with it, it is very much practically useful in different situations.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

The factories we use for enameled wire assure efficient distribution of products across the globe thanks to cutting-edge production technology and rigorous quality control. We collaborate with our international logistics partners to tailor logistics solutions that are tailored to the requirements of our clients. Our global delivery network is comprised of major ports to ensure that the products reach their destinations quickly and safely. Our sales staff also provides online tracking services that keep our customers informed of the status of their shipment, improving supply chain transparency.