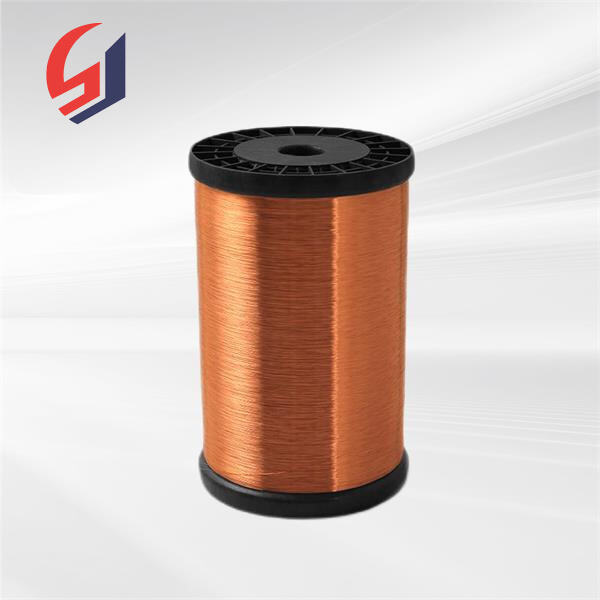

Enameled copper winding wire is a specialty type of wire Shenzhou Cable produces. This wire is crucial for numerous electrical devices. It powers machines and devices that we encounter on a daily basis. So here are the five points with some content that makes this wire awesome and its application.

Enameled copper winding wire isto extremely strong wire. It can take a lot of electricity without falling apart or wearing out. Many machines -- motors, transformers, and generators, for example -- must operate correctly, and this is crucial. These machines keep things moving, such as vehicles and appliances. They use this wire for that so they can get things going without a hitch, which is crucial for maintaining everything in good working order.

In environments such as factories and mines, machines have to operate long hours. They get used all day and need to be extremely durable. The copper winding wire is super great with enamel the longevity of use. An extremely powerful choice for demanding tasks, this wire is able to withstand all of the demands that such machines put on them. It allows machines to work memorylessly without frequent repair.

The winding wire enameled copper is very versatile, so it can have a lot of applications. 93 (qn); that is reconfigured, versatile in size and shape, and can bedeployed to meet disparate needs. For instance, a machine may required a thinner wire, so it can be shaped that way. And if it doesn't, it can have a thicker version! It makes it an extremely convenient type of wire to have. There are numerous uses of it in a different diet from yet small gadgets to huge industrial machines.

The enameled copper winding wire is one of those miraculous things, it can resist heat and corrosion. That means it won’t fail as easily, even if exposed to high temperatures or harsh environments. Appliances such as ovens and even cars burn very hot, but this wire can tolerate it with no problems. This ability to endure harsh conditions makes it an ideal material for various long-lasting products that also undergo frequent usage.

In conclusion, for high-performance electrical equipment, it is best to use enameled copper winding wire. Such devices must be able to carry a high volume of electricity without burning out or grinding down. This is another case where a wire that is strong and durable would work well. DeviceIt can be used in various different devices that require high peak performanceAlso I provide RxSAT.

Our enameled wire factory can customize the products according to customers' special requirements and also provide an extensive after-sales assistance. Diversified specifications: Our factory can produce enameled cables in a variety of specifications including wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Our wire factories that are enameled ensure efficient delivery of products globally thanks to advanced production technology and strict quality control. Working closely with our logistics partners in the world We are able create customized logistics solutions to meet the specific needs of our customers. Our global delivery network covers major ports, ensuring that products reach their destinations efficiently and securely. Sales staff at our company also offer online tracking solutions that inform our customers of the status of their shipment, improving supply chain transparency.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.