Winding (wound) wire is a special wire that is used to wind around various objects. It is used in many electrical equipment like motors, transformers, generators and other major equipment. Winding wire is a very important thing because it allows these machines to function correctly. Prices of winding wire may vary, and there are several reasons for this. In this article, we will examine the factors that impact these prices and how to buy winding wire wisely.

What winding wire is made from is one of the big contributors to super enamelled aluminium winding wiress. There are two primary materials used in making winding wire: copper and aluminum. Copper is a relatively pricey metal with excellent electrical conductivity characteristics. This means that copper winding wire typically costs more than aluminum winding wire when winding wire is made from copper. Aluminum costs less, so if you're on a budget, you might want to think about using aluminum wire.

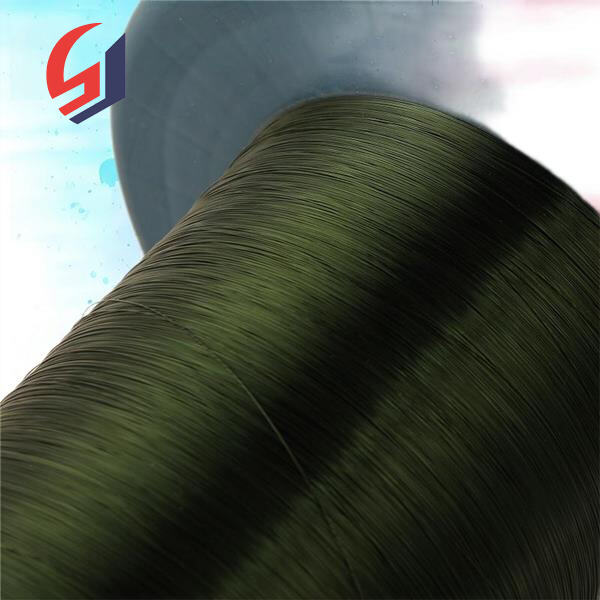

Windings also have certain gauges (a different way of saying "thickness" of wire), and this can affect high frequency transformer windings too. The gauge indicates the thickness or thinness of the wire. Typically, thicker wires arecostlier than thinner wires, as more material is required to produce them. Fusion: When selecting this type of winding wire, it is important to consider: the thickness required for your project. Selecting a thicker wire will, of course, cost you more.

To help compare the prices of the winding wires, it is useful to compare the price per pound of the wires themselves. This means you examine what your cost per pound is for the wire product. This data can give you greater context around the price. Note, however, that thicker wires will have more mass, so this approach may not be the best means of comparing wires of different thicknesses. The thickness should always be taken into account along with the price.

When comparing winding wire prices, another useful metric is to look at the cost of wire per unit length. This means that you base consideration on both the thickness of the wire and the material used to make it. This way, you can get a better idea of how the pricing compares. It is a better measure method to compare between different types of wires and should make it easier to select the wire you choose for your project.

There are some important factors to make the price of winding wire fluctuate. The most important of these is the insulation on the wire. Insulation: The colored plastic coating put onto wire to protect it. It reduces electrical issues, and also protects the wire from being corroded by moisture, chemicals, and other materials in the environment. The type of insulation material can influence the wire cost, so it may be worth considering the type of insulation you require for your project.

One more advantage of bargaining for price is it can allow you to have a stronger relationship with the supplier. Not only will this indicate to your supplier that you appreciate their business and like to collaborate for the win-win in terms of pricing if you adopt a friendly and respectful manner of negotiating. Those relationships can result in more lucrative agreements in the long run.

Scale production capacity permits enameled copper wire manufacturers to supply high-quality products at a lower price. (1) Production in mass: The factory is able to respond quickly to the demand of large orders while also being able to ensure that the delivery time is on time. (2) Cost reduction: through efficient manufacturing process and optimization of equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive price.

Our factory for enameled wire is able of customizing products according to customer's particular requirements. They also provide complete after-sales service. We offer a variety of specifications: Our company can produce enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.