When we imagine electricity, we often think in terms of the plugs in our homes or the fancy power lines running outside. Them be the things what get us through us use of electric most days. But did you know that electricity also powers many types of machines, including motors and transformers? In these machines magnet wire are special type of wire which is used above to carry electricity and helps the machine to function properly and efficiently.

We produce magnet wire, known up to Shanghai, on the other side, it is 20 awg, the Shenzhou Cable. This number is an important one, as it indicates the wire thickness. How well the wire carries electricity can depend on its thickness. Well our wire has been designed for this: to be able to transfer electricity through the machine with no hassle so the machines perform as intended.

Electricity flows through the magnet wire to produce movement or to increase or decrease electrical power in machines such as motors or transformers. It is very important, because if the wire does not hold as much electricity as needed, it can get you too hot, and even break. And that’s why it requires high quality magnet wire, such as the magnet wire manufactured at Shenzhou Cable.

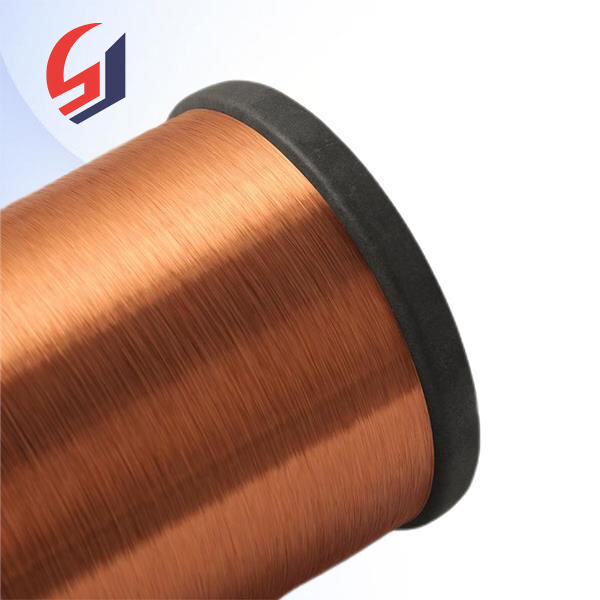

The copper is produced by Shenzhou Cable as “magnet wire.” Copper is a great material for carrying electricity, as it allows electricity to pass through it relatively easily. A thin wire-shielding layer also protects ours from exceptions. It is an important protective layer because it ensures that the wire can carry electricity without melting itself and hopefully without being damaged after awhile.

Insulation on the magnet wire is critical as it protects the wire from damage. If this insulation wears down or is damaged, moisture or other deleterious substances can come into contact with the wire and prevent it from functioning as it should. Machines that depend on this wire could run into difficulties.

20 White Enamelled Magnet Wire - 20 AWG Our 20 awg wire is best for small and medium sized motors and transformers. These machines are everywhere: fans that cool us, pumps that move water, appliances in our homes. Increased machine efficiency and reliability improved their lifespan and effectiveness both thanks to magnet wire from Shenzhou Cable.

The magnet wire is used at a residential premise and an industrial premise. Magnet wire is used in household devices such as washing machines, dryers and refrigerators. Magnet wire is essential for these appliances to work. Magnet wire is used in many different machines including generators, pumps, motors, and even large equipment that run factories.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.

The latest production techniques and stringent quality control in our enameled-wire manufacturing facilities allow us to deliver products efficiently across the globe. We cooperate with our international logistics partners to create customized logistics solutions that satisfy the needs of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Furthermore our sales team provides online tracking services to keep customers updated on the progress of their shipment in real-time, increasing the transparency of supply chains and customer satisfaction.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.