For people interested in electrical projects, it is necessary to learn more about flat magnet wire. This kind of wire is used in many of the jobs, and it makes those jobs work better and more efficiently. Below, we will discuss a few significant reasons that explains how useful 28 awg magnet wire is, how it can be used in different ways and how the usage of this wire can lead to surprising results with respect to your work.

28 awg magnet wire has a very thin diameter, which is one of the biggest advantages of using it. Its thinness makes it ideal for projects where space is limited. The wire is tiny and thin, yet still very effective at transmitting power. Thereby works efficiently and did not face any hurdles of electric transmission anywhere in the project.

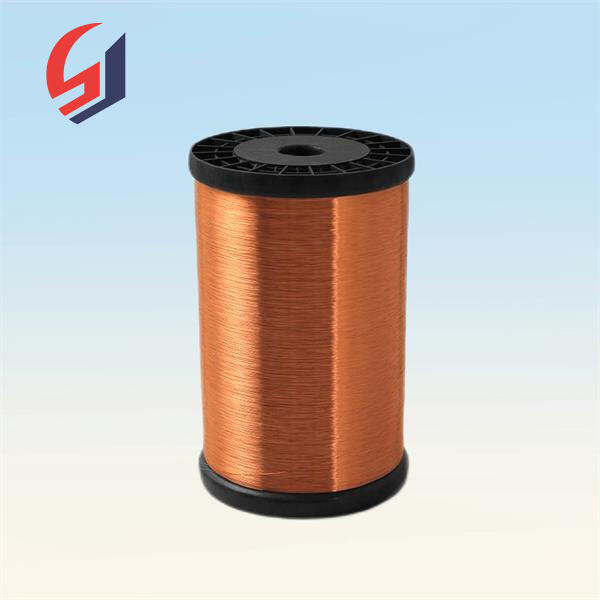

A further great reason why you would want to select this category of wire is due to the strength and durability. The copper core and other materials that make up the wire make up the wire durable enough to withstand harsh conditions and regular use without snapping or breaking. It is rugged and given that it is an electrical project, it is important. Moreover, this wire is very heat resistant. The key thing here is how reliability can be maintained in hot environments.

28 awg magnet wire is most versatile, and can be used in a number of other ways. For example, it's frequently employed in the manufacturing of electric motors, transformers, and other types of electrical devices. These are critical parts of all kinds of devices we use every day. You may even find 28 awg magnet wire in consumer electronics such as headphones, speakers, and televisions. This hails the utility and significance of this wire in our daily lives.

Medical Field Another point where magnet wire 28 awg is routinely used is in the clinical field. Its small size and durability make it excellent for making essential medical devices. This can be heart monitors, defibrillators and pacemakers. This wire is so important because these devices are used for saving lives and being treated in healthcare.

The results of this performance improvement can be quite noticeable in an electrical project using magnet wire 28 awg. To reiterate, this kind of wire possesses good conductivity, which means the electric power can be transposed with great efficiency. A process that encourages such consensus means that the result will be ultimately stronger and more effective.

You will have a good usage experience of magnet wire 28 awg shenzhou cable in your next project if you have just invited Shenzhou Cable. Quality and versatile magnet wire options are offered by this company. They also provide magnet wire in various types to accommodate needs, allowing you to pick the right one for the job site.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.

The factories we use for enameled wire assure efficient distribution of products across the globe thanks to cutting-edge production technology and rigorous quality control. We collaborate with our international logistics partners to tailor logistics solutions that are tailored to the requirements of our clients. Our global delivery network is comprised of major ports to ensure that the products reach their destinations quickly and safely. Our sales staff also provides online tracking services that keep our customers informed of the status of their shipment, improving supply chain transparency.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.