Magnet wire is a coated strand and is an integral part of many devices we use in our everyday lives. All manner of things use this special wire, including power transformers, which convert electrical energy from one form to another, and small motors used in machines to create motion. But just what is aluminum enameled wire, and why does it work so well in these kinds of devices? In this article, we will discuss the coated magnet wires have the real deal, their benefits, what kinds of coatings are on them, and where you can find them in your life.

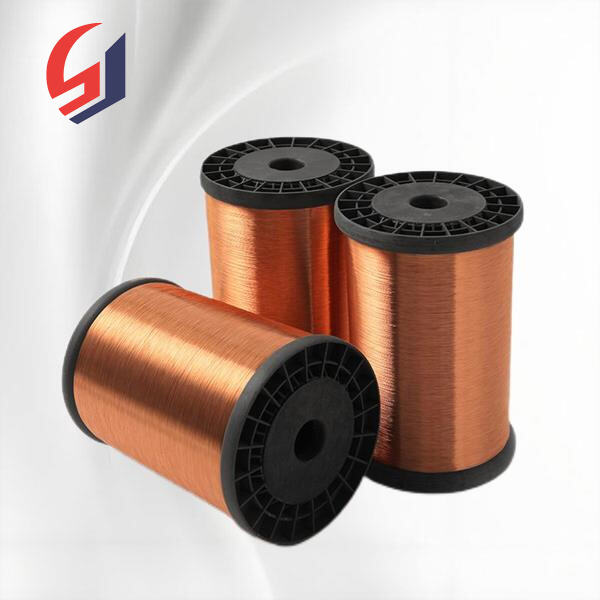

Coated magnet wire is a strand of copper or aluminum. These metals conduct electricity well, meaning they allow electricity to pass through them easily. The wire, though, needs a unique coating to protect it. This coating can be made out of enamel, varnish, or even polyester. That outer coating is like a shield ensuring that the wire won’t touch other wires or the metallic components of devices. This is extremely important because if the wire contacts anything it should not, then electricity can cause electrical shocks that can be harmful.

When you pass electricity through the coated wire, it generates what’s called a magnetic field. This magnetic field is very useful because it can help make motors spin or transfer energy in devices called transformers. The insulation or coating looks to make the electricity flow smoothly and efficiently. This saves energy and makes the devices run better since less energy is wasted.

Prevention of Short-Circuiting – Perhaps the main benefit is that the coating prevents short-circuits. A short-circuit occurs when a wire inadvertently touches another wire or metal part. This may lead to a device breakage or, at worst, a fire. This layer adds some protection and keeps everything safe.

Minimizes Energy Loss: Electricity, when passed through wire, some energy out of it will be lost in form of heat. This is not a good thing, meaning the device is not working at its best. The coating on this magnet wire is designed to keep this energy loss low, and therefore, the device can use the energy more efficiently and conserve electrical power.

Tailored to Requirements: Coated magnet wire can also be manufactured for specialized applications. Which means it can be tailored to operate in super high heat or harsh environments. This versatility makes it a great option for many applications across household items, industrial machines, and so on.

Transformers: Transformers are important devices that transfer electrical energy from one circuit to another. The coils inside the transformer are made from super enamelled aluminium winding wires, whose isolation helps minimize energy loss and improve the performance of the device.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.