Litz wire is used in many electronic devices. It is composed of several thin wire strands twisted together to minimize electrical losses. Shenzhou Cable is a professional China litz wire supplier, we have quality Litz wire for sale here. By understanding why Litz wire is necessary for electronics manufacturing, and how you can choose the right supplier, you can be confident that your equipment will work as it should

Due to its construction, Litz wire is important in electronics manufacture. The Litz wires help to decrease skin and proximity effects, which can introduce electrical waste in systems. With the use of Litz wire, producers can improve the functionality and lifelong of their electrical products. This is very important for applications that employ signals or currents of high frequency like transformers, inductors and antennas.

In addition, the Litz wire is less resistive and more flexible than a solid wire and therefore it is used for those applications that high efficiency or strong resistance to tensile force are requested. Its capability of working at higher frequencies without discontinuity of power loss, makes Litz wire to be commonly used due to all industries in healthcare, automotive and renewable

When you need Litz wire for electronics manufacturing, it's important to think about things like insulation material, wire gauge and strand count. Dealing with a trusted supplier of cable such as Shenzhou Cable can guarantee you get the best quality litz wire for sale according to your specification and performance needs. By selecting the proper type of Litz wire for your electronic machines, you can make them more effective and productive while also minimizing power loss.

Litz wire is often bound up in telecommunications equipment. The multiple wires in Litz wire help to mitigate the skin effect, where at high frequencies signals travel along a wire’s outer surface more than its interior. The latter leads to higher conductivity and lower signal loss, so Litz wire is commonly used in antennas and communication systems.

The unique construction of Litz wire provides many advantages when compared to typical wire. The twisted wire design with magnetic angle makes electric resistance decreased which results in high signal transmission efficiency, support high-frequency signals. In such applications where accuracy and dependability is important, it can lead to increased performance and reduced signal loss.

When Litz wire is part of your design, you will get better efficiency, reliability and performance out of your product. Whether in telecommunications or medical devices, or any other industry where you need to do something high-tech and have it come out right, litz wire per meter price might be a product solution you’ll find great value using.

The latest production techniques and stringent quality control in our enameled-wire manufacturing facilities allow us to deliver products efficiently across the globe. We cooperate with our international logistics partners to create customized logistics solutions that satisfy the needs of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Furthermore our sales team provides online tracking services to keep customers updated on the progress of their shipment in real-time, increasing the transparency of supply chains and customer satisfaction.

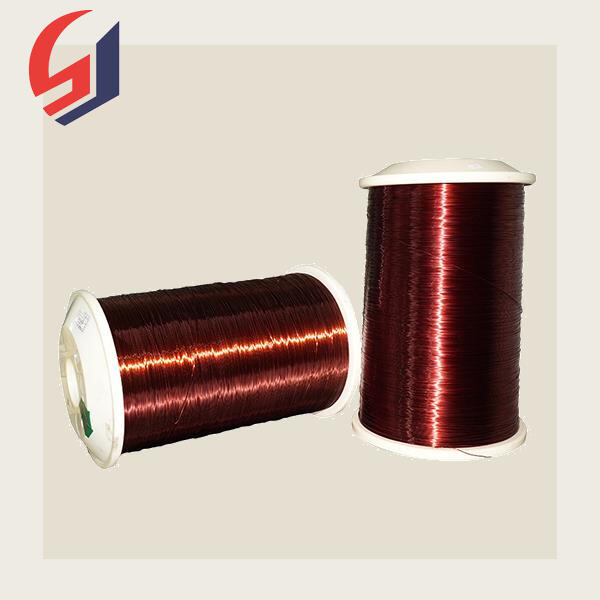

Our enameled wire factory can customize the products according to customers' special requirements and also provide an extensive after-sales assistance. Diversified specifications: Our factory can produce enameled cables in a variety of specifications including wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

The high-quality of enameled wire copper is essential. The factory goes through numerous quality checks to make sure the products are up to international standards and meet customer demands. (1) Raw materials control from pure copper to top quality insulating lacquer, raw materials are screened thoroughly for stability. (2) Monitoring of the whole process From wire drawing to the process of enameling each stage of production is subjected to rigorous tests including tensile strength along with electrical and insulation voltage withstand tests, in order to assure the reliability of the product. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification, as well as UL safety certification. SGS certification, to boost customer confidence.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.