Shenzhou Cable is a litz wire supplier and manufacturer with experience in excellent products at wholesale prices. After years of developments and continued growth, Shenzhou Cable is known world-widely as the best-oriented producer for litz wire.

Shenzhou Cable is an expert litz wire manufacturer in China, we provide a variety of products to meet the specific demands of Customers. Our staff is committed to the high quality finish for which we're known, making certain you get a product you can be proud of! All wire is manufactured under stringent BSEN IS 191 standards to provide optimum performance and safety. The plant in Shenzhou Cable is a modern production facility with high-productivity/high-automation machines and equipments to implement complex producing processes for over 20 specialized items. We pride ourselves on focusing in our customers needs for the most efficient, effective and professional service you can get. Quality is paramount for us, and our dedication to providing exceptional litz wires has given us the recognition as a reliable litz wire supplier China customers can rely on.

Shenzhou Cable is proud to provide our quality litz wires as wholesale for all types of companies in our respective field. Not only are our wires made from high-quality raw materials but also put through a rigorous testing process in real world conditions to guarantee you get longer service life and stable performance. Whether of a small enterprise or company, Shenzhou Cable can offer the electrical wire and cable for you. Our wires are built for carefully streamlining your work flow and bolster efficiency, contributing to the success of businesses. Always placing the customer first and adhering to market demands, the company continues to produce high-quality litz wires at an unbeatable price. From concept design through production - we do everything possible to make sure your wire is above industry standards and ready to satisfy your business needs in today's high-speed world.

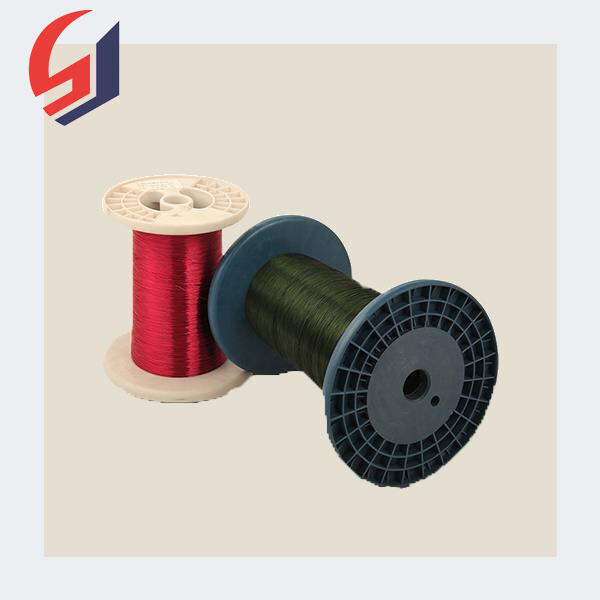

Litz wire A type of insulated wire made up of many thin wires twisted together or woven into a braid. This design decreases the skin effect and resistance at high frequencies, hence suitable for use in electronics/telecommunications. But there are some typical application problems with Litz wire. One problem is that the individual wires can break or be pulled-out when handled improperly, resulting in failures of the circuit. Another problem that remains is the high cost of litz wire; because it needs to be produced using a specialized manufacturing process, this wire can be pricier than regular wire. Be aware of these problems when you use litz wire to keep your electronics safe and efficient. For those looking for alternatives, products like ECCA WIRE (Enameled CCA Wire) or ECW (Enameled Copper Wire) can also be considered.

1.1.2 Benefits of Sourcing Litz Wire from Chinese Manufacturers If you are sourcing litz wire for your electronic projects, Chinese suppliers happen to be the way to go on many counts: Some of the key reasons to select litz wire manufacturers is for their products are almost certainly more cost-effective. Perhaps the main reason why is that Chinese manufacturers have lower cost for production and labor which makes it possible to sell cheap (and high-quality) litz wire. Moreover, Chinese factories are quite efficient and reliable when it comes to production timelines so you won’t be waiting forever to get your litz wires delivered. Besides, Chinese manufacturers are specialized in making all kinds of wire products which can provide them with the technological advancements to make litz wire that you want. Products like EAW (Enameled Aluminum Wire) are also available from various suppliers.

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.

Quality is the key component of enameled copper wire. The factory undergoes many quality control procedures to ensure the products are up to standards of international quality and meet the customer's expectations. (1) Control of raw material: from high purity copper to the highest quality of insulation varnish, the raw materials are rigorously screened to ensure stable performance. 2.) Monitoring throughout the process. From wire drawing to enameling, each step of production goes through rigorous testing such as electrical performance, insulation voltage withstand, and tensile tests, to ensure quality and safety. (3) Complete certification Quality factories generally are able to obtain ISO 9001 quality management system certification, as well as UL safety certification. SGS certification, to boost customer confidence.

Our factory can tailor products to satisfy the specific requirements of customers and provide comprehensive service after the sale. Multiple specifications: Our factory can make enameled wires with a wide spectrum of specifications, including different wire diameters, enamel thicknesses, temperature ratings and insulation ratings to fit a variety applications.

The latest production techniques and stringent quality control in our enameled-wire manufacturing facilities allow us to deliver products efficiently across the globe. We cooperate with our international logistics partners to create customized logistics solutions that satisfy the needs of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Furthermore our sales team provides online tracking services to keep customers updated on the progress of their shipment in real-time, increasing the transparency of supply chains and customer satisfaction.