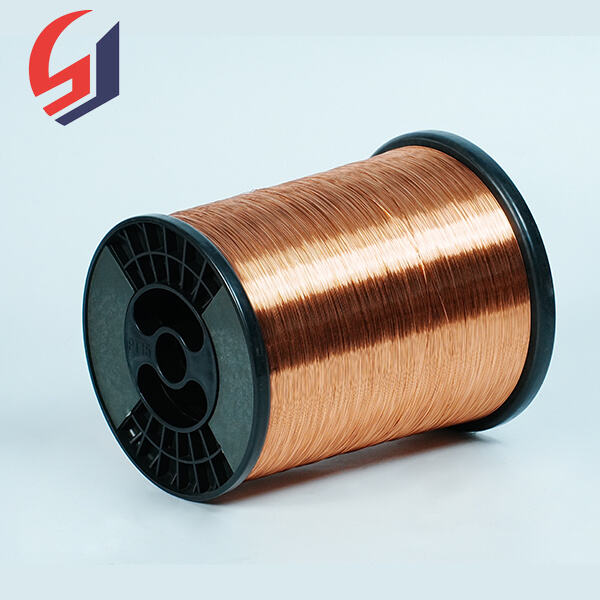

Shenzhou Cable is a professional motor rewind wire manufacturer with low price for sale. Our facility is designed with you in mind to guarantee top performance and long term quality for all your motor rewind wire requirements.

We specialize in providing high quality motor rewind wire at the best prices you will find anywhere. Quality is the first with best service. Whether you need a motor replacement or are rewiring industrial or commercial machinery, we offer various types of motor rewind wire to meet your needs. And with our affordable prices, it's easy to get the items you need without breaking the bank. For instance, our ECCA WIRE (Enameled CCA Wire) is a great option for those looking for reliable performance.

In terms of performance and reliability, Shenzhou Cable exceeds your expectations. Our motor rewind wire is engineered for daily use, offering quality you can count on. We draw from rich and diverse point of inception which is grounded in proven design, engineering methods, and manufacturing technology that inspires our performance led products. Besides, our factory has among the strictest test standards in the world to ensure every product is up to your level of quality. With Shenzhou Cable, you can be confident knowing that your motor rewind wire will work well for a long time. Additionally, we offer a selection of ECW (Enameled Copper Wire) for enhanced efficiency.

At Shenzhou Cable, we are a motor rewind wire factory making sure that every need of wholesale wire is catered with accuracy. Our factory is well-equipped with advanced production machines and professional technicians to ensure our products to be finished in high quality and perfect feature.

Our motor rewind wire plant is available for producing varieties of wire products to fit wholesaler buyers requirements. Whether you need premium wires to carry out professional work or something more simple for general DIY projects, we have it all here. We work hand in hand with our clients to understand their needs and provide tailor made solutions that fit them exactly.

What makes our motor rewind wire plant different from others is our pursuit for perfection in all parts of our operations. "We take pride in the quality of our products from the finest selection of raw materials to superior production performance under strict quality control. Moreover, our factory continues to invest in new technologies and production techniques that keep us ahead of the curve and in product development at any time. Features -DIY Fitting Shed Windows Our facility is always developing new innovations & ideas on a monthly basis.

Our motor rewind wire factory built products address usage problems often found in the field. Whether it’s ensuring peak conductivity, providing top-quality resistance to heat and corrosion, or using the most durable materials, our wires are designed to serve consumers and professional mechanics in a wide range of weather conditions. Enjoy the peace of knowing that you’ve purchased one of the best speaker wire products on the market. For example, our Polyester (QZ/PEW): Polyester Enameled Wire is an excellent choice for those needing high durability.

Our factory can tailor products to satisfy the specific requirements of customers and provide comprehensive service after the sale. Multiple specifications: Our factory can make enameled wires with a wide spectrum of specifications, including different wire diameters, enamel thicknesses, temperature ratings and insulation ratings to fit a variety applications.

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.