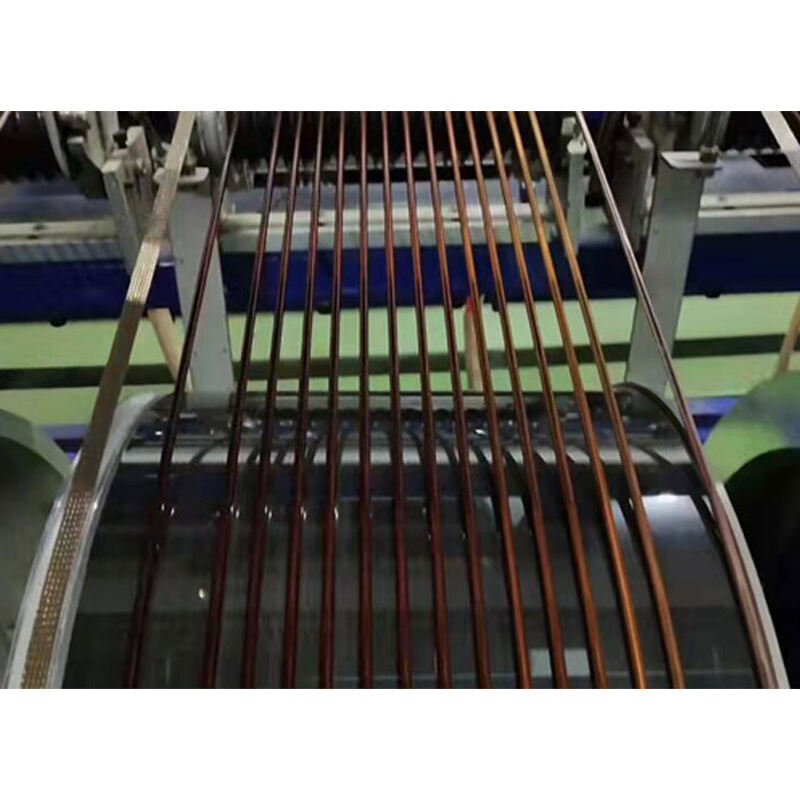

Advantages: Litz wire is constructed by twisting individually insulated thin wires in specific patterns, which significantly reduces AC losses in high-frequency applications due to its ability to mitigate skin and proximity effects. This leads to increased efficiency, lower operating temperatures, reduced footprint, substantial weight reduction, and avoidance of "hot spots" in transformers and inductors . Disadvantages:The manufacturing process of Litz wire can be complex and labor-intensive, leading to higher costs compared to solid wires. Additionally, the effectiveness of Litz wire begins to drop off above 3 MHz, and the packing factor or copper density can be affected by the enamel layer and inherent air gaps from twisting round wires together . Application Fields:Litz wire is widely used in various applications that require high-frequency operation and efficiency, such as stator windings, power transformers, motor generators, hybrid transportation, renewable energy systems, communication equipment, and medical devices. It is also utilized in induction heating applications, sonar equipment, and radio transmitter equipment, among others .

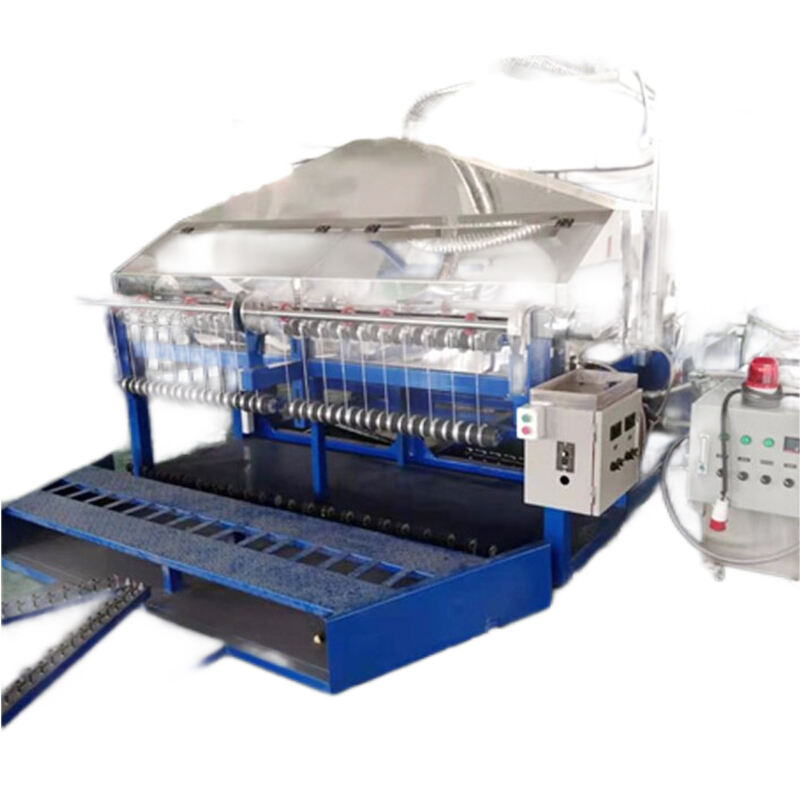

This system is designed to reduce the hardness of the wire by heating it to a specific temperature and then cooling it gradually, enhancing the ductility and flexibility of the wire, which is essential for further processing and manufacturing of wire...

The drying system removes moisture and other volatile substances from the wire surface, ensuring a clean and dry surface for subsequent coating processes, which is critical for the quality and adhesion of the insulation layer .

Applies a layer of insulating paint to the wire, providing electrical insulation and protection against environmental factors such as moisture and chemicals, thereby enhancing the wire's performance and service life .

This system is used for additional coatings or finishing touches on the wire, which may include color coding, marking, or applying specific performance-enhancing properties to the wire .

The paint baking oven is used to cure the insulating paint on the wire through a controlled heating process, ensuring the paint's hardness, durability, and adherence to the wire surface .

The capstan system guides and controls the movement of the wire as it travels through various stages of the manufacturing process, maintaining tension and preventing wire breakage or tangling .

This system winds the processed wire onto a spool or reel, organizing the wire and preparing it for storage or further use in manufacturing processes .

Guide wheels help direct the wire along a specific path during the manufacturing process, ensuring smooth wire movement and precise positioning through various machinery .