When it comes to transferring data signals over a network, twisted pair copper cable is a type of cable that has been uniquely designed for that purpose. It is known as "twisted pair" because it consists of two copper wires twisted together in a coil. This twisting is extremely important in order to minimize interference from neighboring electronic devices. Interference can make the signal faint or unclear but the twisting helps retain the strength and clarity of the signal.

Twisted pair copper wire also is easy to install. In other words, it is quick and easy to install, and requires no special skills. Many things can be put together themselves, minimizing costs from hiring experts. It has many other possible applications as well. To illustrate, telco lines enable us to make calls, computer networks empower us to go online, and audio systems deliver amazing music. Its versatility makes it a solid choice for a variety of usages.

Starting with the twisted pair copper wire, sending data got a lot of benefits. The electromagnetic field that is generated helps to prevent interference and this is one of the big advantages of using this type of cable over others out there. This allows the signals passing through it to be clearer and more stable, something extremely needed when we seek to communicate or obtain information instantly.

But there are also some restrictions to be aware of when working with twisted pair copper wire. The most significant downside is its narrow bandwidth. Bandwidth is a term for how much data you can send at a time. That being because a wire can only transmit data so fast. For networks that require this information to be sent out almost instantaneously — think of streaming videos, or playing an online video game — this can be an obstacle.

In twisted pair copper wire, the wires are twisted together to reduce crosstalk and improve signal quality. A wire loop formed when the wires twisted together. This loop generates a magnetic field to compensate for potential interference from nearby electronic devices. It is really helpful as interference may corrupt or weaken the signal and make it difficult to understand or utilize.

Twisted pair copper wire, through the years, designed and constructed, seem to follow the pace of technology advancement. There are many different types of twisted pair copper wire today, and each type has its advantages and limitations. One specific example is shielded twisted pair (STP) cable. It has an added layer of insulation that mitigates electromagnetic interference. That means it can deliver a more evident beacon in environments with plenty of electronic static.

The next way twisted pair copper wire has evolved is through different categories. All categories denote how much data a cable can transfer in a second. a Cat5 cable could transmit data at a maximum of 100 megabits per second (Mbps) while Cat6 cable could transmit at a maximum of 10 gigabits per second (Gbps) With this, twisted pair copper wire also evolves with the technology to meet the demands for high-speed data transfer and larger bandwidths.

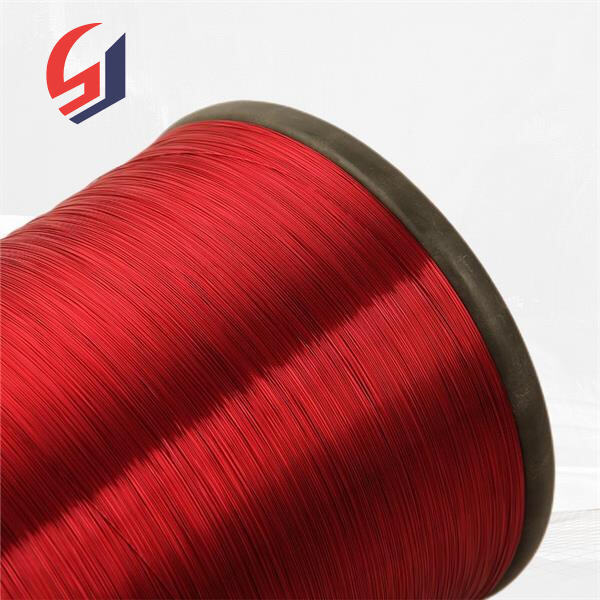

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

Copper wire factories with enamel coating can create high-quality products at an affordable cost because of their scale production capability. (1) Mass production: The factory is able to respond quickly to the needs of large orders, while at the same time guaranteeing the speed of delivery. (2) Reduced costs through an efficient production process and equipment optimization manufacturing, factories can decrease production waste and improve output and reduce unit cost and giving customers more competitive price.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.