Tangled twining copper cables are Shenzhou Cable's message for you. These special cables are vital for networking, a form of communication between various devices, including computers, phones, and etc. Twisted pair copper cables transmit information, or data, from one location to another. They do this using two wires coiled together that carry electrical signals that travel up and down. This twisting helps to maintain the clarity and strength of signals.

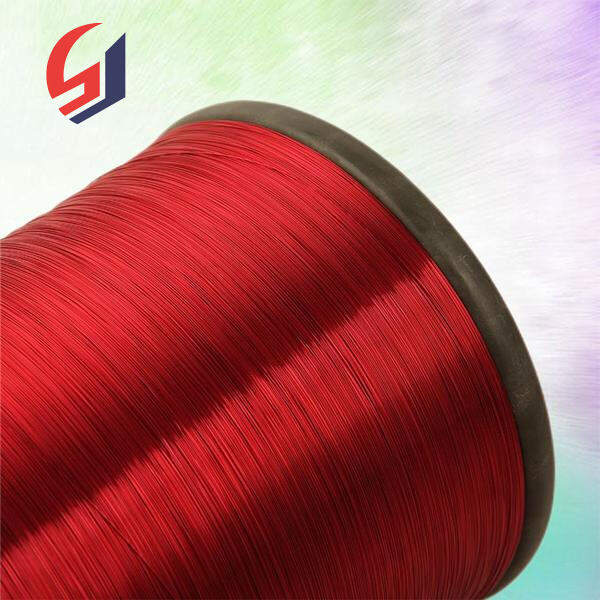

In the present, aluminum enameled wires are still one of the most common types of cable for networking. One major reason they are so widely used is they are reliable, which means they usually work well. They're also not too costly, so they fit well into a lot of people's lives. These cables are easy to install, so you don’t have to be a tech wizard to make them work. You don’t need any special tools or skills, either, so they’re something almost anyone can do.

Twisted pair copper cables are not affected much by external interference, in contrast to other types of cables. The twisted cables help prevent interference, which is when signals get garbled or crossed up, ensuring the data gets sent clearly and quickly. Guess the point is since super enamelled aluminium winding wiress are connected in your device and well apart from others, whenever you are using it, it will always turned out to be greater.

So now we will take a closer look at twisted pair copper cables pros and cons. By far the biggest advantage is that these cables are cheap, or at least not expensive, which makes them the best option for many businesses and homes. They save money and time since they are simple to install, saving on hiring professionals to set up. They also work efficiently in most atmospheres, enabling you to employ them in numerous environments without concern obtained with whether or not which they will proceed properly.

On the other hand, you have to also keep in mind some drawbacks. The downside, however, is that twisted pair copper cables are limited by distance. They transmit data only a short distance before attenuation occurs, making these technologies incapable of long-distance use. Another problem is that these cables may be susceptible to something known as crosstalk. Crosstalk is a phenomenon that occurs when two cables transmit their signals next to each other, interfering with each other, leading to confusion and difficulty in understanding.

Twisted pair copper cables have a long history with many changes since they first were created. Twisted pair cables were originally developed for telephone lines back in the 1800s. They were a significant advancement for communication back then. However, twisted pair copper cables were not widely used for networking until the 1990s. That is when a lot of people began using them for their home and office networks.

Nowadays, you can find 4 flavors of twisted pair copper cables, each with unique characteristics that make them fit for certain jobs: For instance, Cat6 cables can transmit data at speeds of up to 10 Gbps, which is very fast. Likewise, Category 7 (Cat7) cables support even faster data transfers, as high as 100 Gbps. This is a clear evolution of twisted pair copper cable to satisfy the ever-increasing demands of technology.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.

Quality is the primary element of enameled copper wire. The factory undergoes many quality control stages to make sure that the product meets international standards and meet customer needs. (1) Raw materials control: From high purity copper, to the highest quality insulating lacquer, raw materials are subjected to rigorous screening in order to ensure stability. 2) Monitoring of the entire process. From wire drawing to the final stage of enameling, every step of production is subjected to rigorous tests like electrical performance and insulation voltage withstand and tensile tests to guarantee high-quality and reliability. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification and UL safety certification. SGS certification that increases the trust of the customer.

Our factory can tailor products to satisfy the specific requirements of customers and provide comprehensive service after the sale. Multiple specifications: Our factory can make enameled wires with a wide spectrum of specifications, including different wire diameters, enamel thicknesses, temperature ratings and insulation ratings to fit a variety applications.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.