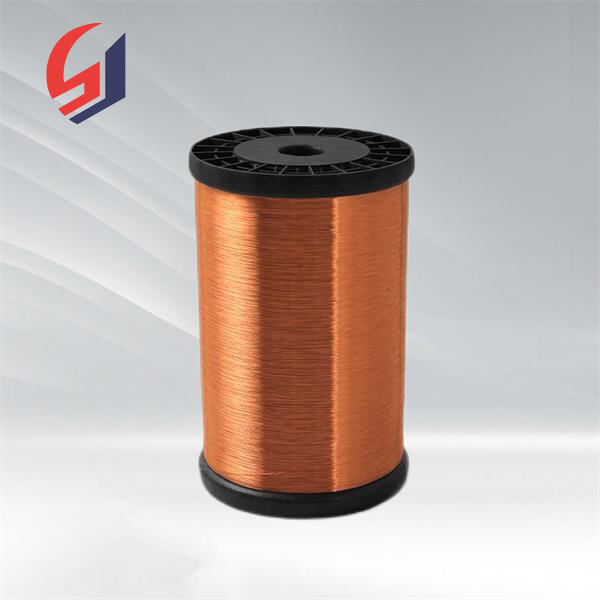

Are you questioning why the enamelled copper ranges among suppliers? This type of wire can be affected by many factors regarding its price. But the quality of the enamel coating on the wire is one of the most important factors. The enamel coating is a protective material that prevents the wire from damage. Good quality enamel coating means that the wire will cost more. The reason being that materials of a higher quality take longer to create and require more labour.

How thick the wire is also changes the price. Thick wire is more expensive than thin wire. This is due to the fact that thicker wires use more copper, which is the primary component of the wire. The more copper that is in the wire, makes it more expensive to manufacture. The bottom line, as you shop for different wires, keep in mind that thickness thickness is the key factor that ultimately plays into the price.

Market-based prices of super enamelled copper wire are fluctuating. Market conditions also refer to supply — how much copper is available — and demand — how much people want to buy. If lots of people want copper, the price of super enamelled copper wire rises. This is often the case during busy periods when a lot of people and companies need copper in their projects. Conversely, when there isn't a great deal of demand for copper, the price falls. This can occur during slow periods when less projects are taking place.

Market conditions can also shift based on other factors, such as supply and demand, which is how much copper is available relative to how many people want to buy it. Moreover, political events (for example, political conflicts) and natural disasters (like floods and earthquakes) occurring elsewhere in the world can impact the supply of copper. These events cut price of super enamelled copper wire ups and downs.

This is more important because if you are planning to buy super enamelled copper wire, you need to check the exact price before you buy it. An offer that’s just too good to be true might sometimes be a red flag. This may mean that the wire is not good quality so they may have future problems. If the wire broke or mutilation, it can damage your project for example.

04 Jun] When checking the price of super enamelled copper wire, considering a few aspects. Consider the thickness of the wire and the quality of the enamel coating. A thicker wire and a quality enamel coat typically increases the price, but trust us that it will be well worth it for reliability. Also, search for any specific certifications the wire might hold. Such certifications can demonstrate that the wire meets specific quality lines. Also Consider the Supplier’s Reputation A supplier whose reputation for high-quality products is sound is a safer bet.

When it comes to purchasing super enamelled copper wire, there are a few key questions you should ask yourself before moving forward. The application is one of the major things or what exactly you will be using the wire for. Different applications need different types of wire, which is why it’s super important to choose the right strand for your specific project. For example, if the wire is going to be used in electronic devices, it will need to be extremely thin and pliable.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.