One of the most commonly used material for electrical wiring is Ester Type Enamelled Copper Wire. It has a significant role in many electronic devices and electrical systems. However, enter you known the price of enamelled copper wire, due to different reasons will change? We will also cover what factors determine the price of enamelled copper wire, how price trends can impact the cost of enamelled copper wire, how to compare prices across different enamelled copper wire suppliers, why product quality is an important consideration as well as a few top tips for getting the best price for you.

The wire is made of copper which is a precious metal needed by many industries. Copper does not have a fixed price, but instead is determined by supply — how much is available — and demand — how much consumers are willing to pay for it. In general, if lots of people want copper, the price of enamelled copper wire increases. That is because increased demand means suppliers can raise their prices. Conversely, when there is plenty of copper to be had, and few buyers want to pay, its price may fall as sellers try to attract buyers.

Another critical variable that might alter the piece would be the cost involved to create the cord. Enamelled copper wire is made by coating a copper wire with a coat of insulation. This was an important step because it protects the wire from damage. It takes special tools and a trained workforce to do this. These requirements lead to production costs that can also affect the final price of the wire produced.

The prices of green enamel copper wire, like many other things, can be market-dependent. For example, when there is a spike in demand for electronic devices, more enamelled copper wire will be required in order to manufacture those products. بمعنی این است که تقاضا برای سیم مسی لعابی نیز افزایش پیدا میکند که میتواند قیمت ها را بالا ببرد. On the other hand, if fewer people are purchasing electronic equipment, this will reduce market demand for the wire and eventually its price will fall.

More widely, the prices of enamelled copper wire can be affected by other market trends. Changes in government rules and regulations also can come into play. An example would be, if new taxes are created, or if tariffs (taxes on imports) change, these factors may affect the cost of producing enamelled copper wire. This is because, if the production costs go up, the end price of the enamelled copper wire might also increase.

Comparing the prices to buy the enamelled copper wire from various suppliers is a quite vital aspect that should be kept in mind. The basic problem of comparing prices is somewhat complicated. Note: Different suppliers may sell different types, grades, sizes, and specifications of enamelled copper wire. Grades refer to the wire quality while sizes refer to how thick or how thin the wire is. The devil is in the details in this case, so ensure you take the time to examine them and select a wire that suits your particular needs.

When you are buying enamelled copper wire, one of the important thing to consider is quality. A quality product will be more insulating, withstand environmental hazards, and last longer than a cheap product. A high-quality product may appear expensive initially but saves you money long-term. This is because it won’t need to be replaced as often, saving you money in the long run.

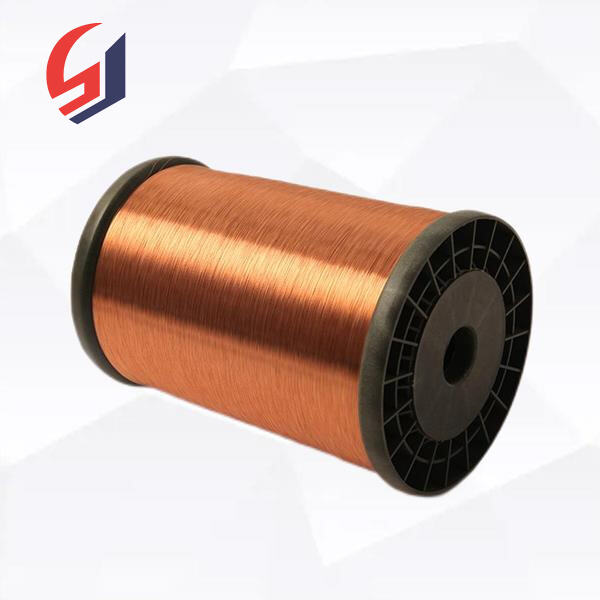

Our enameled wire factory can customize the products according to customer's special requirements and also provide full after-sales support. Diversified specifications: The factory can produce enameled wires in a wide selection of specifications. This includes different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of application scenarios.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.