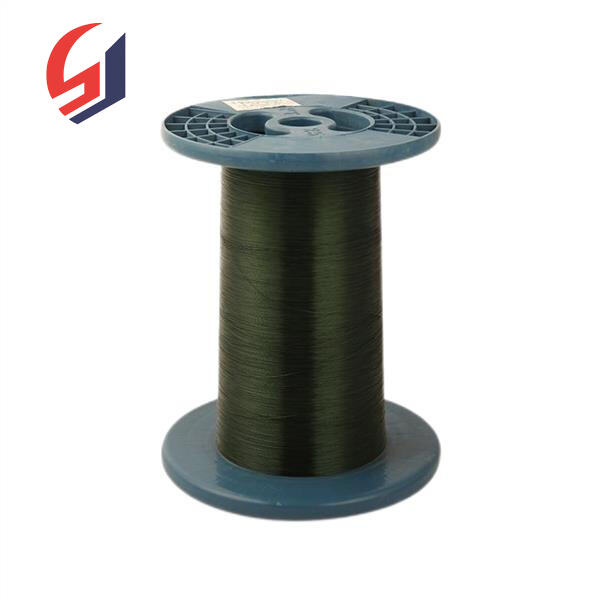

We use a special type of wire called 36 SWG copper winding wire for most of our electrical jobs. This wire is significant in applications such as transformers, motors and generators. These tools allow us to change and use electricity for useful purposes. So copper that can carry electricity very well because it does not resist electric current flowing through it. And that is why copper is often selected for these components. The wire comes in a size defined by the SWG (Standard Wire Gauge) measuring system. The 36 is a gauge that indicates how thick the wire is. A lower number indicates thicker wire, while a higher number indicates thinner wire.

The advantages of using copper winding wire 36 SWG for electrical work are really critical and there are many valid reasons to using copper winding wire 36 SWG. The main reason is that copper wire is flexible. Which makes it able to bend and be shaped without breaking fairly easily. All of this makes all of it way easier to work with when building up or repairing electrical devices. Along with flexible, copper wire is also very sturdy in addition to sturdy. Even when it is heavily used, it can last quite long. This durability means you won’t need to replace it frequently, saving money.

And another incredible property of copper is how well it conducts electricity. Copper is better at this than many other kinds of wire at it, so it can carry electrical currents with a lower resistance. The primary application of copper winding wire 36 SWG is in the construction of transformers, motors, and generators. Some of these elements are also used in many different machines and tools we use in practical everyday life, such as refrigerator, air conditioners and power tools. This wiring also is a crucial part of the electrical wiring connecting everything in buildings and homes, helping to direct power to lights and appliances.

Choosing copper winding wire 36 SWG for your project includes a couple of critical considerations. Make certain that the wire size you will use is correct for your application. The wire’s thickness will dictate the amount of electrical current it can carry safely and how strong it is for your particular need. Too thin a wire and it will not conduct the electricity well, and too thick a wire and it will be unwieldy.

You also need to ensure that the wire is compatible with the other components in your project — such as transformers or motors. That is, the wire has to be compatibly fitted with the rest of the elements so that it can function fine together. The quality of the wire is another extremely important consideration. Not all copper wire have the same manufacturing process, so if using low quality wire it may result into problems in future. To give you one more energy goods symbol that most definitely ought not to be brought down in quality is a transformer that contains cheap wire, ensuring it will flop and cost YOU to repair or supplant.

That means it can conduct electrical current with great efficiency. This is because copper is a poor conductor of electricity. It has low resistance, meaning when electricity travels through the wire, it doesn’t lose much energy on its journey. As a result, copper winding wire 36SWG is widely used in a variety of electrical applications.

Copper winding wire 36 SWG is one of the components that plays a huge role in many machines and tools manufacturing processes. Different types of equipment rely heavily on this wire, and a bad quality one can lead to a lot of problems later. If you use a bad quality wire in a transformer, it may burn or not function properly. Failure of an essential component can result in costly repairs or in some cases necessitate full replacement of the device.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.