Now talking about electronic circuits, there are different types of wires to be used here. One wire that people commonly use is called 24 AWG magnet wire. This wire is quite small and is used in plenty of projects. Let us know more about 24 AWG magnet wire, why it is a great option for electronic projects, and more about why so many people enjoy using it in their work.

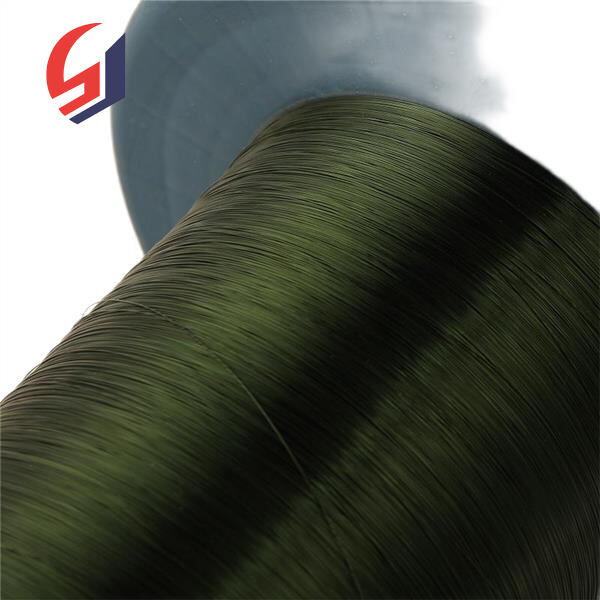

So, why is 24 AWG magnet wire such a popular choice in the field of electronics? The main reason for that is this is a very thin wire. Its thinness makes it ideal for small-scale and intricate designs. Due to its smallness, it can fit just about anyplace tight that larger wires simply would not. We do this often within motors and transformers, where short wire connections are critical to complete the operation.

If some of the common reasons why 24 AWG magnet wire is so popular are discussed, one of the reasons is its extreme sturdiness. This wire is made of a metal- copper- because it is great for carrying electricity. Copper is also not only resistant to rust but also withstands corrosion, which makes it safe from getting damaged by different weather conditions. This is an excellent choice for some electronic circuits that require long-time stability.

24 AWG magnet wire is fantastic because it can be used for a lot of things. For instance, it is frequently used to create small motors. This means that the wires for these motors must be thin for optimal operation. Many everyday electronic devices that we surmise to be valuable; can also have 24 AWG magnet wire inside as we encounter it like transformers, which play a vital role.

As we said previously, one of the great things about 24 AWG magnet wire is how small it is. This small size will be particularly useful when you are working on limited-space projects. So, for example, if you are working on a project that involves a lot of wiring in a small space, when soldering together the various components, you will find your life so much easier by using 24 AWG magnet wire.

24 AWG magnet wire is not only small, but also very flexible. That means you can easily fold and bend it the way you want, without having to worry whether it is going to snap and break in half. This flexibility is a significant benefit in workflows where iterations require precision and careful attention to detail. This feature laid the foundation for more complex designs that enabled you to perform work with greater ease.

Copper is not only a good conductor of electricity, but it is also a very strong material. Resistance to corrosion – it tolerates contact with various elements without damage. It is one of the reasons that 24 AWG magnet wire is if such a durable option for different electronics circuits. It is able to withstand some varying environments and continue to perform over a period of time.

Our enameled wire factory is able of customizing products to meet customers' special requirements and also provide complete after-sales service. Different specifications: The factory can manufacture enameled wires with a wide range of specifications, including various wire diameters, enamel thicknesses, temperatures and insulation ratings to fit a variety applications.

Scale production capacity permits enameled copper wire manufacturers to supply high-quality products at a lower price. (1) Production in mass: The factory is able to respond quickly to the demand of large orders while also being able to ensure that the delivery time is on time. (2) Cost reduction: through efficient manufacturing process and optimization of equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive price.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.