Kawat magnet Shenzhou Cable juga dikenal sebagai kawat tembaga enamel yang merupakan jenis kawat tertentu. Kawat ini sangat penting, karena digunakan dalam berbagai perangkat listrik. Kawat magnet ditemukan di motor, transformator, dan generator. Proses produksinya cukup menarik, karena dimulai dengan kawat tembaga biasa. Selanjutnya, kawat tembaga ini dilapisi dengan lapisan tipis zat pelindung yang dikenal sebagai enamel. Enamel ini memiliki fungsi yang sangat penting: mencegah keluarnya listrik dan membuat kawat bekerja dengan benar. Kawat magnet memungkinkan aliran listrik dengan bersih, tanpa kelebihan panas atau membuat perangkat di mana ia digunakan rusak.

Ada banyak hal yang perlu dipertimbangkan saat memilih flat magnet wire akan digunakan untuk proyek listrik Anda. Poin pertama yang perlu dipertimbangkan adalah ukuran kawat. Ukuran tersebut adalah angka yang menunjukkan seberapa tebal atau tipis kawat tersebut. Angka ukuran yang lebih besar berarti kawat yang lebih tipis, sementara angka yang lebih kecil sesuai dengan kawat yang lebih tebal. Memilih ukuran yang tepat sangat penting untuk proyek spesifik Anda.

Jenis isolasi juga merupakan pertimbangan penting saat memilih kawat magnet. Isolasi adalah bahan di sekitar kawat yang digunakan untuk melindunginya. Ada berbagai macam bahan isolasi seperti poliuretan, poliester, poliamida-imid, dll. Setiap jenis isolasi memiliki sifat uniknya masing-masing yang berguna dalam situasi tertentu. Jenis isolasi lainnya dapat menahan suhu lebih tinggi, sementara yang lain lebih baik dalam melindungi dari kelembapan.

Ada beberapa keuntungan utama menggunakan kawat magnetik yang mengikat diri yang membuatnya menjadi pilihan yang baik untuk digunakan dalam aplikasi listrik. Keuntungan terbesarnya adalah bahwa ia dapat menghantarkan listrik dengan sangat sedikit hambatan. Ini juga berarti bahwa perangkat yang menggunakan kawat magnet Shenzhou Cable tidak hanya akan mengonsumsi listrik tetapi juga membantu mereka untuk meminimalkan panas berlebih atau pembakaran. Oleh karena itu, perangkat kawat magnet memiliki kualitas lebih tinggi dan seharusnya bertahan lebih lama serta berfungsi lebih andal dibandingkan dengan yang dibuat dari kawat kelas rendah.

Membuat kawat magnet adalah proses yang panjang dan melibatkan beberapa langkah utama. Pertama, mereka menarik kawat tembaga melalui alat khusus kawat magnet perekat , yang disebut cetakan, untuk membuatnya lebih tipis. Kawat dibentuk sesuai ukuran oleh mesin-mesin ini. Setelah kawat mencapai ketebalan yang tepat, ia dilapisi dengan bahan isolasi, biasanya enamel. Kemudian kawat dipanaskan pada suhu tinggi setelah pelapis diterapkan. Langkah pemanasan membentuk lapisan pelindung yang kokoh dan kuat pada kawat.

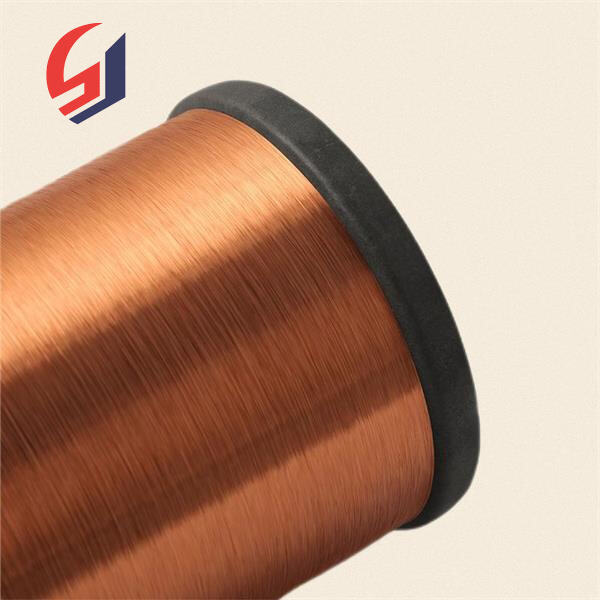

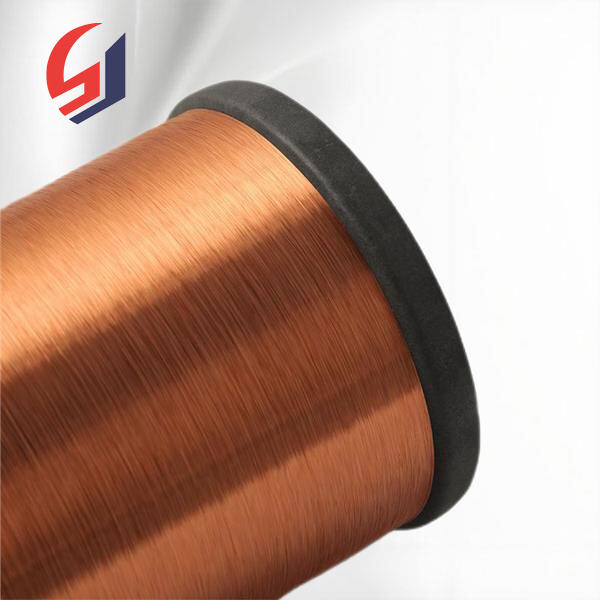

Setelah kawat dilapisi dan dipanaskan, ia digulung ke dalam bobbin—mirip dengan cara benang digulung ke dalam bobbin jahit. Setelah kawat berhasil dilewatkan seluruh panjangnya di atas bobbin, ia melewati pengujian kualitas untuk memastikan konsistensi. Ini adalah proses kawat magnet tembaga untuk memastikan bahwa setiap panjang kawat memiliki kualitas terbaik. Uji akhir pada setiap kawat adalah untuk memeriksa kualitasnya, jika ada kawat yang tidak lulus uji kualitas maka akan dibuang. Kawat yang memenuhi standar dikemas dan dikirim ke pengguna akhir.

Terakhir, Anda harus menyimpan kawat magnet dengan benar ketika tidak menggunakannya. Menyimpan kawat dengan benar melindunginya dari kerusakan atau degradasi. Kawat harus dijaga tetap kering, bersih, dan pada suhu rendah. Kawat Shenzhou Cable sebaiknya disimpan dalam kemasan aslinya.

Pabrik kabel tembaga berlapis enamel dapat menghasilkan produk berkualitas tinggi dengan harga lebih murah karena kapasitas produksi mereka secara massal. 1.) Produksi massal: Perusahaan dapat merespons pesanan besar dengan cepat dan memastikan pengiriman tepat waktu. (2) Pengurangan biaya melalui proses manufaktur efisien dan optimasi peralatan, pabrik dapat mengurangi limbah dan meningkatkan tingkat output sehingga harga satuan berkurang dan memberikan pelanggan biaya yang lebih kompetitif.

Kualitas tembaga email sangatlah penting. Pabrik melewati banyak tahap pemeriksaan kualitas untuk memastikan produk sesuai dengan standar internasional dan memenuhi persyaratan pelanggan. (1) Kontrol bahan baku Mulai dari tembaga murni hingga cat isolasi berkualitas tinggi, bahan baku diperiksa secara menyeluruh untuk memastikan stabilitas. (2) Pemantauan seluruh proses. Dari tarik kawat hingga pengecatan enamel, setiap tahap produksi melewati uji ketat, termasuk performa listrik, uji daya tahan tegangan isolasi, dan uji tarik untuk memastikan kualitas tinggi dan keandalan. Untuk meningkatkan kepercayaan pelanggan, pabrik berkualitas biasanya bersertifikat ISO 9001 untuk sistem manajemen mutunya serta sertifikasi keamanan UL.

Pabrik kawat enamel kami dapat menyesuaikan produk sesuai dengan permintaan khusus pelanggan dan juga menyediakan dukungan purna jual penuh. Spesifikasi beragam: Pabrik tersebut dapat memproduksi kawat enamel dalam berbagai spesifikasi. Ini mencakup diameter kawat yang berbeda, ketebalan enamel, suhu, dan peringkat isolasi untuk memenuhi berbagai skenario aplikasi.

Pabrik yang kami gunakan untuk kawat email menjamin distribusi produk secara efisien di seluruh dunia berkat teknologi produksi terkini dan pengendalian kualitas yang ketat. Kami bekerja sama dengan mitra logistik internasional kami untuk menyediakan solusi logistik yang disesuaikan dengan kebutuhan pelanggan kami. Jaringan pengiriman global kami terdiri dari pelabuhan utama untuk memastikan produk mencapai tujuan dengan cepat dan aman. Staf penjualan kami juga menyediakan layanan pelacakan online yang menjaga pelanggan tetap diperbarui tentang status pengiriman mereka, meningkatkan transparansi rantai pasok.