For example, what is a aluminum enameled wire? It's a unique machine that puts a coating on wire to protect it from wear and tear. This coating keeps the wire safe from many nasty things, so that it can be more durable and effective. One such company is Shenzhou Cable which manufactures these machines. They will help you coat wires better than you’ve ever done before, and quicker.

Before enameling machines were invented, there were no such options: people had to coat wires by hand. This was a multi-Master process and took for ages, as it needed a great deal of labor-intensive work. The wires laid by hand were not perfect, and it is common for them to have defects in the coating. With an enameling machine, however, you can coat wire much faster and more precisely. This enables you to make more wires in less time with consistent coating every time!

How it works: Based work on enameling machines They then heat the wire and coat it with a special enamel. It's actually a strong material that protects the wire (known as enamel). Once the layer of enamel has been applied, it cools and hardens to form a tough outer layer over the wire. They are state-of-the-art machines; they employ electricity and a specialty reel to rotate the wire as it’s coated. This rotation also ensures an even coating around the wire, without any thin or thick areas.

The enameling machines of Shenzhou Cable boast of some amazing features. For example, they feature automatic temperature controls that maintain the appropriate heat for coating. The machines also have touch screens that help operate them. Also, these features ensure that you get an even coating on your wire each and every time, and so you know exactly what you're going to get!

Special designs used in Shenzhou Cable’s enameling machines ensure the maximum efficiency for you. These also include high-speed production options that allow you to coat thousands of wires quickly. They're also compatible with multi-layer coatings, allowing you to enamel multiple layers in a single pass. Also, there are quick-change reels so you can easily swap out different wire gauges. These features can save you a lot of time and money.

The Wire insulation is the very crucial one because it protects your electronics and makes is work as it should. The electricity needs to be contained within the wires for safety and performance reasons, and insulation does just that. Hence, enameling machines are able to offer the precise insulation that meets your demands ensuring that all is functioning properly.

For instance, we also provide machines with cutting-edge technology, such as high-resolution cameras that keep an eye on the coating manufacturer's progress. These cameras ensure that the wire insulation that you are putting is always high quality. It also includes automatic quality control systems, which verify the coating while it is taking place. This ensures your peace of mind of proper coating of all your wires.

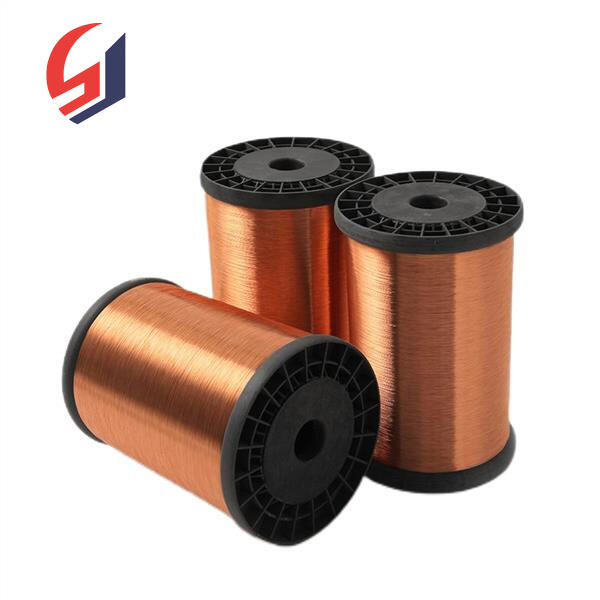

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.