Have you ever wondered how we produce those wires that we use daily? You can also read the full article in the website. They energize electronic devices like televisions and computers, they can add strength to buildings and bridges during construction, and they are included in jewelry that gleams and glitters. These wise wires are made in factories which use these machines known as aluminum enameled wires.

→ Wire drawing machines pull a metal wire through a die, which is a tool with a hole in it. This thin them and make it longer. Think of stretching a piece of silly putty; the more you pull it, the longer and thinner it becomes. The machine then repeats this process multiple times until the wire is the size we ask it to be. Wire drawing machines have different parts in different types for their proper working. These mechanical parts, such as a motor that drives the machine, a spool that stores the wire, a die that forms the wire, and a lubrication system that keeps everything running smoothly and is critical for the operation, add complexity to a machine darw with less steep drops, such as a slide just outside the room.

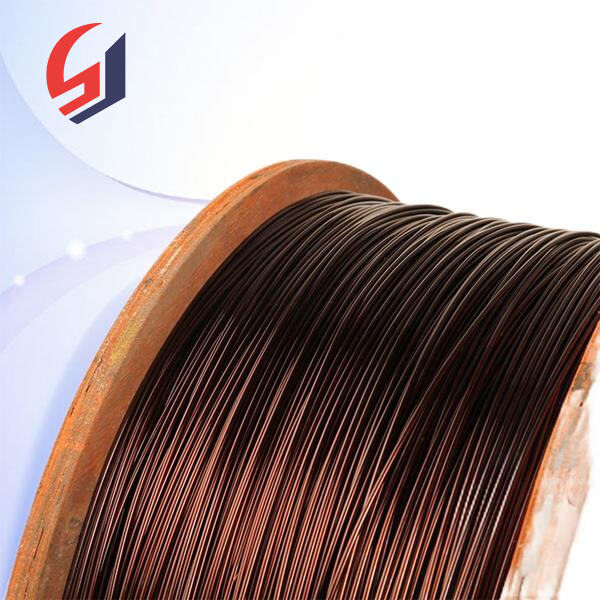

A signle thing that is great about super enamelled aluminium winding wiress is that these machines are used to produce wires in a very punctual way. The die is a precious hard material (tungsten carbide) that insures the wire has the same size throughout its length. This is critical because if the wire is not round you get problems when using it for various applications. These machines are so adept they can make wires as thin as a human hair. That’s incredibly thin!

Before drawbeads, factories had to use a process of cutting, gluing, fabricating, and welding wires. Long, long ago pre machine invention people had to make wires by hand. Wires were created at this stage in a slow and tedious process that made the production of wires too slow. Wires are now made by wire drawing machines in bulk and fast. This is incredibly beneficial to businesses that require large amounts of wires used for their products as it streamlines the production process significantly.

The wire-drawing machines are very important in the preparations of wires that are required for construction and commercial purposes. For instance, in the field of construction wires increase the strength of concrete. This is critical for large structures, such as bridges and buildings, that must be load-bearing. The wires should be extremely solid and of even thickness through their total length. Wire drawing machines are capable of creating wires that meet all the specifications for these applications, so that all safety standards are met.

Using wire drawing machines in production comes with plethora of benefits. First, they save tons of time, and they also help limit the cost of labor. These machines allow wires to be produced fast and in large quantities, thus reducing the amount of manual labour required. So that not only saves time but money for the factories because you need to focus your resources somewhere else.

Secondly, high quality wires are produced by wire drawing machines. The wires are the same thickness because of the machines, which is really important for a lot of applications, like construction. Quality wires also last longer and are more resistant to corrosion, which can result in savings in the long run. A longer lasting wire, means less frequent replacements which is a great benefit to companies.

Our wire factories that are enameled ensure efficient delivery of products worldwide thanks to the latest manufacturing technology and rigorous quality control. In collaboration with our logistics partners in the world we can create customized logistics solutions to meet the specific needs of different customers. Our global network of delivery partners includes key ports to ensure the goods arrive at their destination quickly and safely. Sales staff at our company also offer online tracking services that keep our customers up-to-date on the progress of their shipments, improving supply chain transparency.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

Our factory is able to customize products to meet the requirements of the customers. We also provide complete support after sales. Multiple specifications: Our factory is able to produce enameled wires that meet a broad variety of specifications, which include different diameters of wire, enamel thicknesses, temperatures, and insulation ratings to suit various situations.

Copper wire factories that are enamel can produce high-quality products at a lower price due to their scale production capability. (1) Mass production: The factory is able to respond quickly to the needs of large orders, while at the same time ensure the timeliness of delivery. (2) Cost reduction. Through optimizing the production process and equipment, the factory is capable of reducing waste, increase output, and cut down on unit expenses which allows customers to be more competitive in their prices.