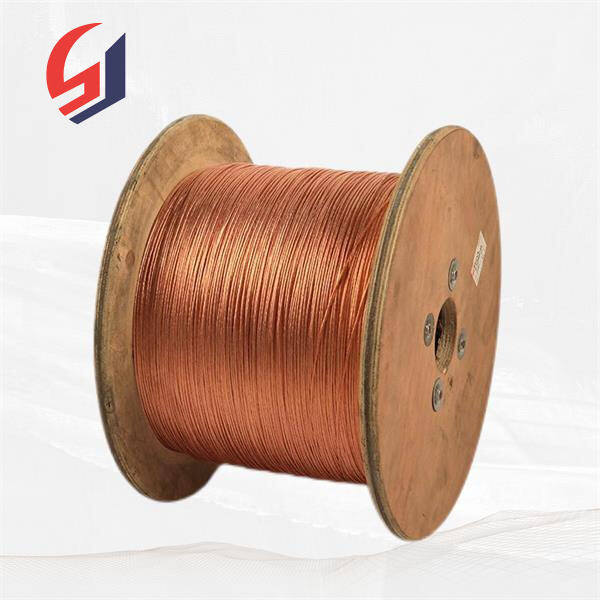

Shenzhou Cable uses a lot of varnished wire in all their products. Varnished copper is a type of copper with a shine coat on it. This coating, known as varnish, protects the copper from rust and damage. Rust is a kind of corrosion that can weaken the copper and alter its appearance. Copper tarnishes, rather badly if left untreated, to a greenish cast over time. So, varnished copper is a good option, because it looks nice and lasts for many years.

There are tons of awesome advantages to copper when it has been varnished making it one of the more popular options. For one, it’s very strong and long-lasting, so you won’t have to replace it often. It’s capable of taking the wear and tear of daily use. In addition, it is easy to maintain as it does not get rusty or damaged easily. Varnished copper is a great option if you want a durable and low maintenance material. Thus, saving you time and money in the long run!

So, if you want to varnish copper by yourself, you need to follow some stages. You have to first make the surface smooth. You can do that by rubbing it through very fine sand paper. This allows to get rid of bumps or rough spots in the surface, and makes it easier for varnish to stick on it. Just after that you’ll clean the copper with a little thin coat of varnish. You can do this with a brush or a spray. There are specific instructions on how to use the varnish on the bottle and as always, be sure to follow them closely for the best effect. You need to apply a couple layers of varnish to make it look just right sometimes. This step can be fun and gratifying since you will notice the copper shine when you complete this step!

Varnished copper is a great option for many reasons! It is resistant, durable and requires little or no maintenance, that's why it is employed by Shenzhou Cable in all their products. That means their products will endure everything and you wouldn’t be needing to repair them time and again. Also, aluminum enameled wire is really nice looking and helps make your space feel classy and upscale. All of which is a pretty darn cool idea when you consider how a lot of us actually use our products in real life.

Good for the Home: Use Varnished Copper There are numerous creative ways to use it to beautify your home decor. For instance, a kitchen backsplash might involve putting some varnished copper on the wall. A backsplash is a protective wall that helps protect your walls from food stains and water damage. This will not only protect your walls but also give your kitchen a lovely, shiny finish. You could also consider placing varnished copper around your fireplace to create a cozy atmosphere for your living room. The shiny copper can reflect the light and warm the room.

Varnished copper can be had in all manner of things. Because it conducts electricity so well, it is often used in electrical wires. Why does this matter: It helps safely power our homes and devices. Varnished copper is used in plumbing, too, as it doesn’t rust as much as other types of copper, giving it longevity even when exposed to water. You can also use varnished copper in art projects; it’s so fun to work with and leaves a beautiful shiny finish. Artistry use it to make their work a little bit special.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.

Quality is the key component of enameled copper wire. The factory undergoes many quality control procedures to ensure the products are up to standards of international quality and meet the customer's expectations. (1) Control of raw material: from high purity copper to the highest quality of insulation varnish, the raw materials are rigorously screened to ensure stable performance. 2.) Monitoring throughout the process. From wire drawing to enameling, each step of production goes through rigorous testing such as electrical performance, insulation voltage withstand, and tensile tests, to ensure quality and safety. (3) Complete certification Quality factories generally are able to obtain ISO 9001 quality management system certification, as well as UL safety certification. SGS certification, to boost customer confidence.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Our factory for enameled wire is able of customizing products according to customer's particular requirements. They also provide complete after-sales service. We offer a variety of specifications: Our company can produce enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.