Submersible winding wire is a unique kind of wire that is designed for use in underwater settings. What is special about this wire is that it can be submerged into the depth of water and it can work really well without damaging. For a lot of underwater equipment, it is significant. Shenzhou Cable is one of the manufacturers of this durable and resistance against moisture flat jacketed submersible pump cable. They're working on wires that will stand up to the harsh environments beneath the water's surface.

One of the biggest challenges of such a design is a mechanical one—to make the rotor blades both as light and strong as possible to maximize performance.

There is a coatings on the aluminum enameled wire that isolates it from water. This is a crucial part of construction, as it allows the wire to function well once submerged. It also keeps the wire from rusting because the metal can rust when it is exposed to water for a long time. Apart from the coating, the wire has also an insulated surface. This insulation is important because it stops the wire from short-circuiting, which is when the electricity skips from one place on the wire to another, causing issues. Shenzhou Cable is sollicitous of its product's protective coating and insulation, specializing in making submersible winding wire. That means the wire remains functional and has no problem working underwater for an extended period of time.

There is a very efficient conductor used in manufacturing submersible winding wire. These are conductors that can transmit electricity with minimal resistance. Low resistance (in a wire) means, very little energy is lost when electricity passes through it. However, this is a cool feature because this allows the wire to be super dope. This makes the wire ideal for high-performance applications, including pumps and motors. They are standard underwater tools that are used. Shenzhou Cable specializes in submersible winding wire for high-performance jobs in submerged environments. As a result of this, their wires are both durable and highly effective conduits for electricity.

The wires that will be used underwater need to be very strong and flexible. This is because they are regularly exposed to harsh conditions like that of being surrounded by seawater, which is tough on materials. WIthout fail, one of the biggest issues with such an environment is the water itself. Shenzhou Cable manufactures both strong and flexible submersible winding wire. As a result, the wire is flexible and doesn't break, which makes it easy to be installed in various underwater machines. These wires work great for all kinds of underwater equipment like sensors and variable speed drives. They are versatile and can be adapted for many different underwater applications.

Submersible winding wire frequently exposed to water rust corrosion over time. To address this issue, Shenzhou Cable produces submersible winding wire that has weather-resistant and corrosion-proof properties. Waterproof Wire — This wire is made to last a long time while in contact with water. This wire is made in such a way that it does not rust, this wire can be resistant to ultraviolet rays and harmful weather. Designed to last, this wire can stand up to some tough and rough situations. This allows for years of reliable service for an underwater application.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.

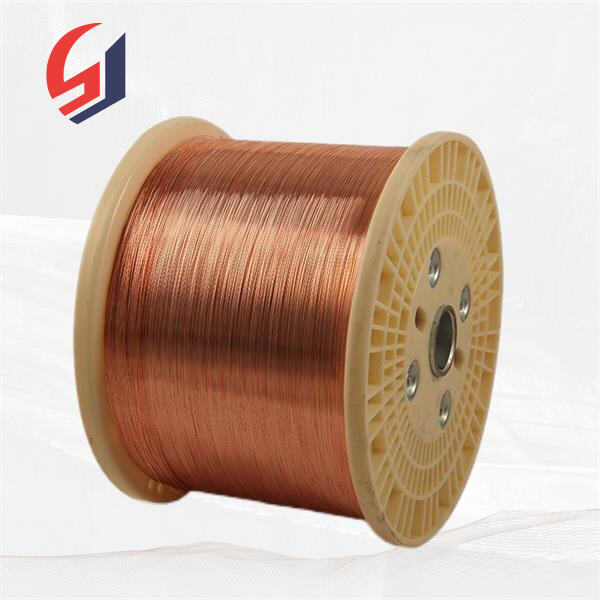

Copper wire factories that are enamel are able to produce top-quality products for an affordable cost because of their scale production capability. 1) Mass production: The manufacturing facility can rapidly respond to orders of large size and guarantee timely delivery. (2) Reduced costs through an efficient production and optimizing equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and allowing customers to enjoy a better price.

Our enameled wire factory can customize the products according to customers' special requirements and also provide an extensive after-sales assistance. Diversified specifications: Our factory can produce enameled cables in a variety of specifications including wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

The high-quality of enameled wire copper is of paramount importance. The manufacturing facility goes through a variety of quality checks to make sure the quality of the products is in line with standards set by international standards and satisfy customer needs. (1) Control of raw materials From pure copper, to high quality insulation lacquer, all raw materials undergo strict screening to ensure stable performance. (2) Continuous monitoring of the process: From wire drawing to enameling, each stage of production goes through rigorous testing including tensile strength along with electrical and insulation voltage withstand tests, to ensure the quality of the product. In order to increase customer confidence Quality factories are typically certified with ISO 9001 for their quality management system, as well as UL Safety certification.