Soldering is a specific method of connecting two pieces of metal or wire. You do this by melting a special type of metal called solder. Solder is heated to melt it and it is then cooled so that it firmly holds the parts together. Enamel-coated wire can be slightly tricky. This is because the enamel coating prevents the solder from adhering well to the wire. But don’t worry! If you put in the time and learn the ideal techniques, it will fast become second nature, and you can learn how to solder enamel-covered cable like a pro!

There are some key things you should know before begin soldering. The first step is to prepare the necessary tools and materials. One of these is a soldering iron, which is a tool used to heat and melt the solder. For soldering you will need solder, flux, wire cutters and pliers as well. All these tools have a specific function that will help you achieve success.

Another tip is any desk area should be clean. It’ll make sure that your tools are readily available to you as you work as well as keeping you safe in the workspace. Be sure to wear safety glasses to shield your eyes from any flying sparks or small pieces of solder while you work. When soldering, keeping yourself safe is paramount.

The first technique is to strip the enamel coating off the wire before you actually solder. This is significant because the enamel can inhibit the solder from adhering properly. Use a wire stripper or a sharp knife to gently remove enough of the coating from the tip of the wire so that you create the connection. This will expose enough of the bare metal underneath to really help the solder adhere much better.

Second technique — using the right amount of flux. Just keep in mind that flux is used, that it is a kind of special paste so that solder sticks effectively on it. You don’t need to use a lot — just a bit will suffice! If you have too much flux on, it's a bit of a mess and hard to work with. So be sure to apply a small amount to the wire before starting to solder. It will make things easier and more effective for your soldering.

The third technique is to use the correct temperature when soldering. Dangerously, if the soldering iron is too hot it may burn or burn off the wire enamel coating, which can be troublesome. Conversely, if it’s not hot enough, the solder won’t flow properly and a good connection will be difficult to make. It can be worthwhile to try out the different temperatures that work for your particular wire and solder.

Now, super enamelled aluminium winding wires is a bit of a challenge, but don’t let that put you off! It’s possible, with the right tools and techniques, and practice. Remember to work slowly and pay attention to the dos and don’ts we covered. Trying out different methods will help you discover what works best for you and your projects.

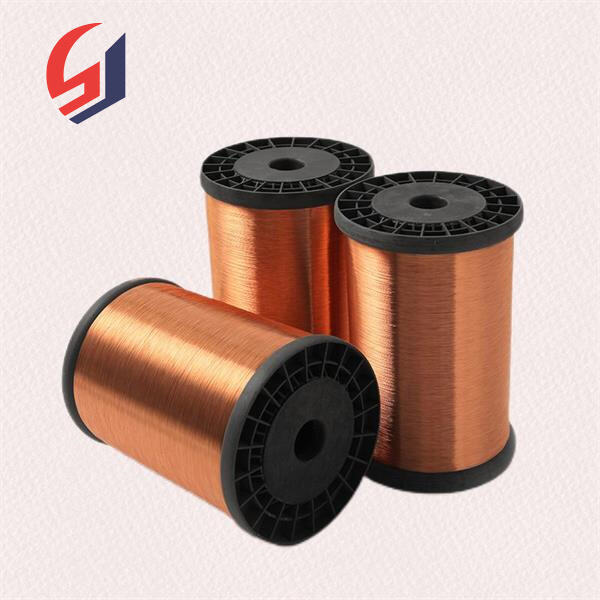

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.

Modern production technology and strict quality control procedures in our enameled-wire factories enable us to provide products with speed across the globe. Through close collaboration with our logistics partners in the world, we are able to provide tailored logistics solutions to satisfy the needs of various customers. Our global delivery network is comprised of key ports to ensure products arrive at their destination quickly and safely. Our sales team also offers online tracking services that keep our customers up-to-date on the status of their shipments increasing transparency of supply chain.

The high-quality of enameled copper is of paramount importance. The manufacturing facility goes through a variety of quality control procedures to ensure that the product meets standards of international quality and meet the customer's requirements. (1) Control of raw materials from pure copper to premium insulating lacquer, the raw products undergo rigorous screening to ensure their performance is stable. 2.) Whole-process monitoring. From wire drawing to enameling, every stage of production is subjected strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure quality and safety. In order to increase customer confidence, quality factories are usually certified by ISO 9001 for their quality management system and UL Safety certification.

Scale production capacity permits enameled copper wire manufacturers to supply high-quality products at a lower price. (1) Production in mass: The factory is able to respond quickly to the demand of large orders while also being able to ensure that the delivery time is on time. (2) Cost reduction: through efficient manufacturing process and optimization of equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive price.