Are you a tinkerer and like making awesome things with electronics? If you have, then you may have come across something called "Solderable Enamelled Copper Wire. “It may seem overwhelming initially, but fear not! We are here to explain it to you in an easy way to understand.

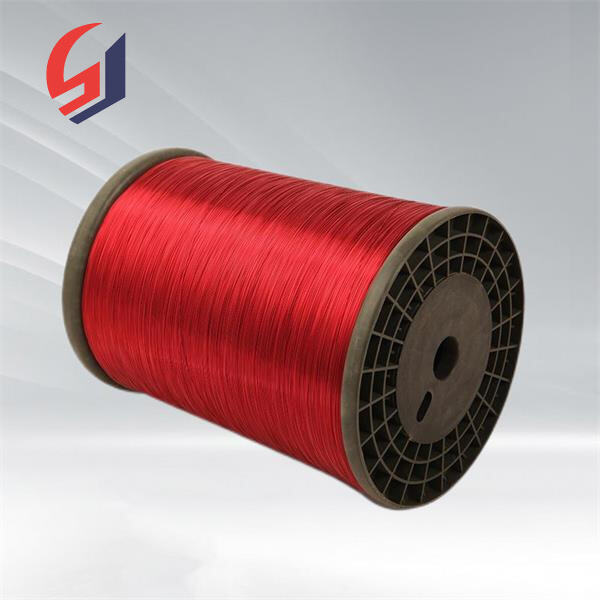

This is a special type of wire called Solderable Enamelled Copper Wire that is used by the electronics industry in devices. This wire is copper and copper is a metal that allows electricity to flow from place to place. It has a thin coating of enamel. This layer of enamel is extremely important because it prevents the electricity to go where it is not supposed to go. In this way, the copper part of the wire makes the electricity travel to its destination, which allows your electronic devices to function normally.

Easy to Handle: Solderable Enamelled Copper Wire is easy to work with which is one of the best things. It’s easy to work with, thanks to the thin enamel coating. A soldering iron -- the tool used to melt metal to connect -- can easily cut through this coating. With the coating removed, it’s easy to solder the wire to other parts of your project.

Different Gauges: Solderable Enamelled Copper Wire is available in various thicknesses, called “gauges.” This allows you to pick a size of wire that is perfectly sized for your project. You can find thicker wire if you have a larger job. If you want something thinner for a more compact project, that’s adjacent to it. It allows for enough versatility to make it ideal for a variety of electronics.

Durable: The next best reason to go with using Solderable Enamelled Copper Wire is its durability. This wire is more resistant to rust than most wires. So it is robust enough to withstand extended use without failing or degrading. This sturdiness is of considerable significance, especially for frequently used gadgets.

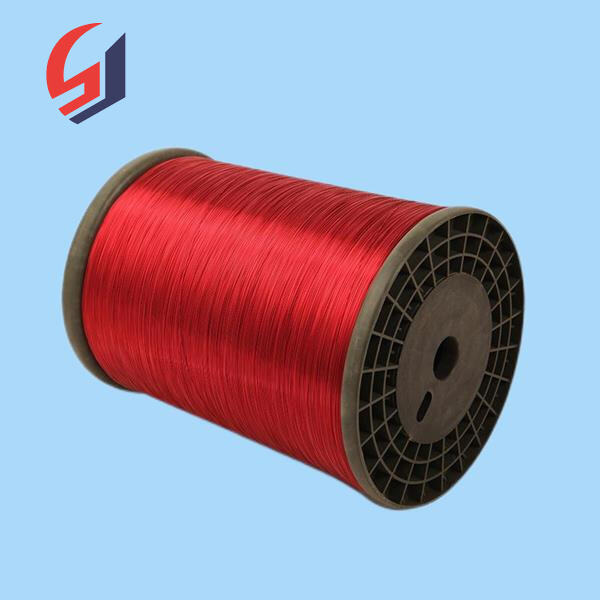

Sensors: This wire is utilized within sensors, which are unique devices capable of detecting alterations in the environment. Sensors, for instance, are able to tell when it becomes dark or when someone is nearby. This enables electronic devices to react and respond to their environment.

They have a springy wire with a thin but tough enamel covering, so they suck up to solder well. Also, it rusts less readily, so it has a longer life span than most kinds of wires. So visit Shenzhou Cable And grab your Solderable Enamelled Copper Wire today, if you are looking forward to start your next electronics project.

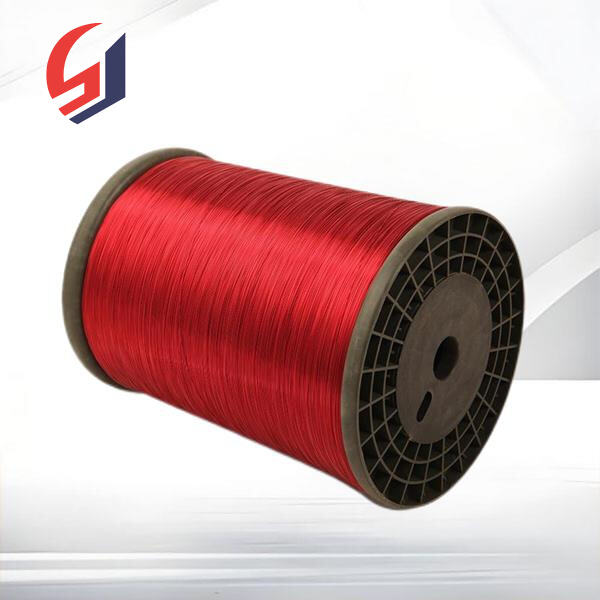

Our wire factories with enameled wires assure efficient distribution of products globally thanks to advanced production technology and rigorous quality control. We partner with our international logistics partners to create customized logistics solutions that satisfy the demands of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers up-to-date on the status of their shipments and improves transparency in the supply chain.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.

Quality is the primary element of enameled copper wire. The factory undergoes many quality control stages to make sure that the product meets international standards and meet customer needs. (1) Raw materials control: From high purity copper, to the highest quality insulating lacquer, raw materials are subjected to rigorous screening in order to ensure stability. 2) Monitoring of the entire process. From wire drawing to the final stage of enameling, every step of production is subjected to rigorous tests like electrical performance and insulation voltage withstand and tensile tests to guarantee high-quality and reliability. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification and UL safety certification. SGS certification that increases the trust of the customer.

Our factory can design products to satisfy the specific requirements of our customers. We can also provide full service after the sale. Diversified specifications: Our factory produces enameled cables in different specifications like wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.