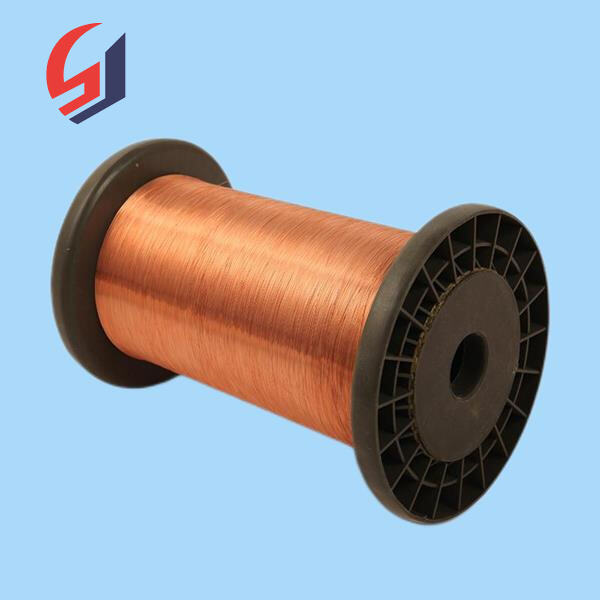

Another in-demand commodity in our daily lives is electricity. It helps switch on our lights, fuels our devices and runs our appliances. There are a number of things we use on the regular that simply wouldn’t exist without electricity. Here’s something you might not have thought about: How does electricity travel through our homes and devices? GMW winding wire is pivotal to this process. This wire helps form coils in most electrical appliances so that we can function properly and work effectively.

It's great to list shenzhou cable aluminum enameled wire benefits. The first reason is that it is made from very durable materials, so, it does well in rough environments as well. This wire does not fail when there is intense heat or pressure, for instance. Furthermore, the electricity used in GMW winding wire is more efficient than many of other types of wire. This means it can transmit the power without energy loss which is super smart for many projects.

GMW winding wire is an ideal choice for all your electrical project. It is durable and long-lasting, which means it can withstand the test of time. For example, this wire will serve you for a long period if you run the machine every day. And also GMW winding wire can withstand both higher temperatures and not break, making it perfect for the many industrial applications in which the machinery operates at greatly elevated temperatures.

It is extremely essential to select the appropriate size of GMW winding wire for your project. The unit of measurement, known as gauge, describes how thick the wire is. More powerful devices require higher power as the thicker the wire, more electricity it can carry. It is available in a number of sizes from Shenzhou Cable, so ensure to select one which best meets your needs. In case you are not sure about the size to choose, you can always contact the experts at Shenzhou Cable to assist you. They can offer advice and assist you in finding the correct wire for your particular project.

Ideal for factory or industrial based workplaces; GMW winding wire. It is highly versatile and can be employed in various electrical systems including transformers, motors, and generators. Transformers change the voltage of (A/C) electricity so it can be used safely in homes. Motors turn in many machines, causing them to move and generators produce electricity. Furthermore, GMW winding wire is also relatively cheap compared to many other types of wires, making it a great choice if you're looking to save money while still getting excellent quality.

In conclusion, discovering diverse facts about GMW winding wire and how it is utilized in various electrical components can be an adventure of learning. Anything from simple toys that can move all the way up to complex machinery that we use to assist us in factories, there are so many options out there. GMW winding wire will help you to comprehend how electrical systems are constructed and how they interconnect with each other. You may even start to think about how you can use this incredible material in your own projects in the future.

Our enameled wire factory is able of customizing products to meet customers' particular requirements. They also provide complete after-sales service. Diversified specifications: The factory is able to produce enameled wires that meet a broad variety of specifications, which include various wire diameters, enamel thicknesses, temperature ratings, and insulation ratings to fit a variety different applications.

The latest production techniques and stringent quality control in our enameled-wire manufacturing facilities allow us to deliver products efficiently across the globe. We cooperate with our international logistics partners to create customized logistics solutions that satisfy the needs of our customers. Our global delivery network is able to cover important ports, ensuring that your products get to their destination promptly and safely. Furthermore our sales team provides online tracking services to keep customers updated on the progress of their shipment in real-time, increasing the transparency of supply chains and customer satisfaction.

Enamel copper wire factories can create high-quality products at cheaper prices due to their production capacity on a large scale. (1) Production in mass: The manufacturing facility can react quickly to the demands of large orders and at the same time ensure the timeliness of delivery. (2) Cost reduction. By optimizing the production process and equipment factories are able to reduce consumption, increase output and lower unit costs and allow customers to be more competitive in their prices.

Quality is the primary element of enameled copper wire. The factory undergoes many quality control stages to make sure that the product meets international standards and meet customer needs. (1) Raw materials control: From high purity copper, to the highest quality insulating lacquer, raw materials are subjected to rigorous screening in order to ensure stability. 2) Monitoring of the entire process. From wire drawing to the final stage of enameling, every step of production is subjected to rigorous tests like electrical performance and insulation voltage withstand and tensile tests to guarantee high-quality and reliability. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification and UL safety certification. SGS certification that increases the trust of the customer.