Flat wire producers are unique people that produce thin, flat wires. These wires are very important to many different occupations and industries. They are critical because they can transport electricity and heat efficiently. One popular flat wire manufacturer is Shenzhou Cable. They have a good repute in making quality wires. This article will tell you how they produce them, why they matter so much and what sets them apart.

In every aspect of business, Shenzhou Cable strives to produce a premium section of wire flat on a daily basis. They are extremely meticulous in what they do and are detail-oriented. These flat wires are created by rolling big round wires flat with a giant rolling mill. This is the lowest of the low hanging fruit. The wires are then passed through specific tools, known as dies, which ensure that each wire has the appropriate thickness and width. This is an important aspect of ensuring the wires are suitable and effective for use.

Once the wires are complete, Shenzhou Cable conducts a very thorough inspection to ensure no faults or errors are present. Testing the wires on modern machines, they guarantee that their every product is of the best possible quality. If they find one that’s not good enough, they reject it, and it never goes to customers. By doing so, their customers can always expect for them high quality products they deserve to know and trust.

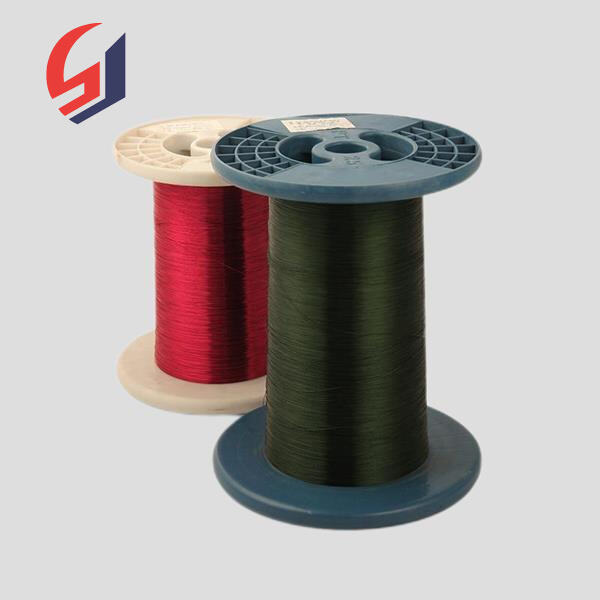

Different type of materials are used for these wires like copper, aluminum or stainless steel. All materials have their pros and cons, and that’s what makes them ideal for different tasks. For instance, stainless steel wire works well in high heat applications, whereas copper wire does not melt and is widely used in electrical applications because it effectively conducts electricity. With such a diverse range of materials, Shenzhou Cable is a one-stop-shop for a multitude of industries and customers.

Shenzhou Cable's flat wires are manufactured through their clever and creative approaches. They profess to put money in research and discovery to create new and better methods to like their wires. So you might have fully automated machines run by computers. This allows the company to guarantee that every wire is manufactured to a very precise specification, which is critical for quality.

Shenzhou Cable analyses each demand for lath wires specifically delivers shrouded form wires which can suits the need for the clients. This is the reason why they provide customized options to their customers. They can vary the thickness, width and material of their wires to suit the individual customer needs. This flexibility means that customers can have a solution that's perfect for them, whether they need a thin wire for fragile electronics or a thicker wire for heavy-duty applications, that meets their specific needs.

They use very reliable production methods as well. They have established quality control standards to ensure each wire is properly made to a high standard. Also, they have redundancy in their systems to ensure they can keep making wires when a machine has a hiccup. They can keep operating and fulfilling orders even if something goes wrong, which is crucial for customer experience.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

Our factory can customize products to satisfy the demands of customers and provide comprehensive support following sales. Different specifications: The factory can manufacture enameled wires in a wide range of specifications, including different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of situations.