Several reasons make the flat copper wire a preferred option. First, they are extremely easy to use. These wires are easy to work with regardless of your skill level. They also come in various sizes, so you can find the ideal size for your project. This variety is very beneficial for users who require certain sizes specific to their devices.

Flat copper magnet wires have another interesting thing which is that they can be flexible. That means you can shape them into new shapes without fear of breaking. Similar to HYMT itself, this flexibility is well-known, so creativity in designing electrical devices is more than welcome. They are хорошо flexible but also strong and durable. This allows them to be recycled in the future, and they can be used for years to avoid potential wear and tear from use, making them a great option for many projects.

Flat copper magnet wires have a great advantage in that they carry electricity effectively. That means they can shift the electricity from one place to another, fast and efficiently. For efficient wires, there is no wasted power which again saves energy. This is a huge plus, particularly today, where we want to make efficient use of energy.

Also, flat copper magnet wires can carry large amounts of electricity without breakage, which is another great benefit. They are highly robust, able to hold heavy electrical loads without compromising. In addition, these wires are heat resistant. This makes them safer to use in many electrical devices, as they do not melt or catch fire as easily.

There are many good things about flat copper magnet wires such as they are highly flexible. This versatility is extremely important as it enables the engineers and designers to produce electric devices in different shapes and sizes. For instance, some devices may need to be small and compact, while some devices may need to be larger or come in unique shapes. These wires can be adapted to so many different needs because they are flexible. This segue into the versatility of electrical devices to be more useful for different usages.

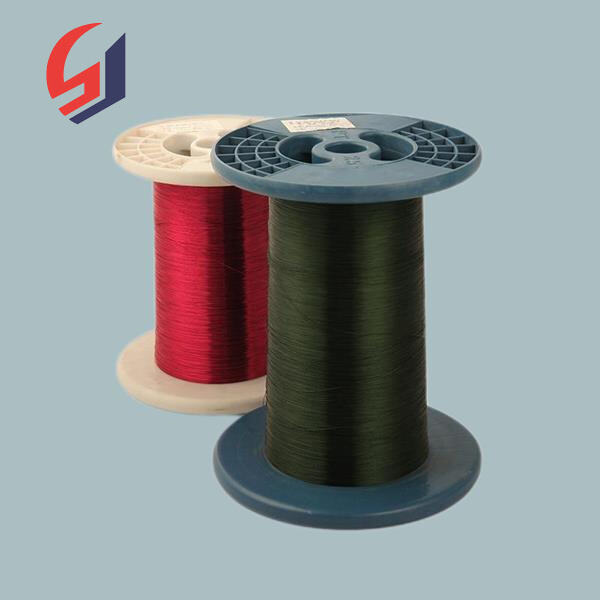

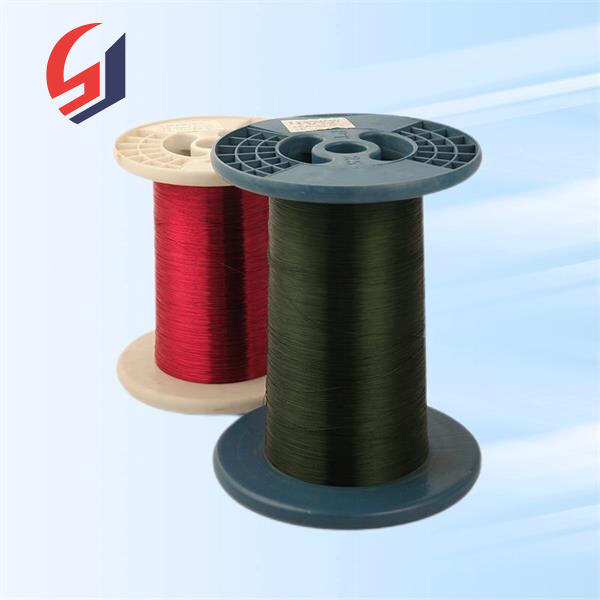

You can say flat copper magnet wire is used in several applications. You are also enought to learn that they are used in electronic devices like computer in computers, smartphones, televisions and many others and are also widely used in other applications. Such devices depend on flattened copper magnet wires to work properly. They are also used in medical equipment, which is extremely crucial for hospitals and for doctors. Trains, cars, and other forms of transportation utilize these wires to function in present-day terms as well. Even in green energy to supply that much-needed energy, such as wind turbines, using flat copper magnet wires. They can even be found in toys and games, powering fun interactive and exciting features!

Magnetic wires, if they are flat copper, are preferred for their better performance. They’re efficient, powerful and adaptable, which is why they work so well. These wires are able to convey a significant amount of electricity without overheating, resulting in a very dependable source. And, their malleability into various shapes allows electronics to take on many different forms. So this flexibility means that devices made up of flat copper magnet wires can function with reduced friction and greater impact than those made of other types of wires, in addition to carrying improved molecular preloads causing better performance and durability within devices.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.

Copper wire factories that are enamel are able to produce top-quality products for an affordable cost because of their scale production capability. 1) Mass production: The manufacturing facility can rapidly respond to orders of large size and guarantee timely delivery. (2) Reduced costs through an efficient production and optimizing equipment The factory is able to reduce waste and increase output rate so that the unit price is reduced and allowing customers to enjoy a better price.