Magnet wires play a vital role in manufacturing various types of electrical and electronic products. They exist in devices such as transformers and motors. These devices must send electricity through coils of wire to function properly. International Electrotechnical Commission (IEC) has devised few guidelines to assure that these wires work efficiently and can be utilized across globe in order to ensure that these wires are functioning properly and can serve globally. A critical standard that you will come across when using copper wires is EN 60317 13, This deals with the compositions of those wires as well as the insulation used to keep them safe.

If this wire is copper, about EN 60317 13 describes precisely what magnet wires have to be like. These wires have the capability to perform in extreme environments when heat can spike to 155°C or more. Essentially, the wires need to be capable of functioning under heat without failing. The insulation is the protective layer which wraps around the copper wire and should not decompose or get damaged at higher temperatures. This rule also laid out how thick the insulation needs to be and how clean the copper is, or that there is no contamination in the copper.

Transformers and coils are made using Magnet wires per EN 60317 13. The electrical devices must be strong since those components are very crucial in order for those electrical devices to work perfectly. These components include power transformers for stepping down or up the cooker rod to the household voltage and audio transformers that enhance the quality of sound, as well as inductors utilized in any other electronic devises. With the help of these magnetic wires, the manufacturers can ensure that no matter how hot the equipment is getting or under how much electrical pressure, everything is working correctly.

Companies have to carry out strict tests on EN 60317 13 magnet wires to ensure quality. They ensure electricity flows through the wire as needed and check for any issues in conductivity. They also measure the effectiveness of the insulation to protect the wire, known as insulation resistance. They also test how long the wire can survive being subjected to heat, a property known as thermal endurance. Besides, corporations must monitor all the things they employ in the production process — so that anyone retains high-quality items and all of them meet standards.

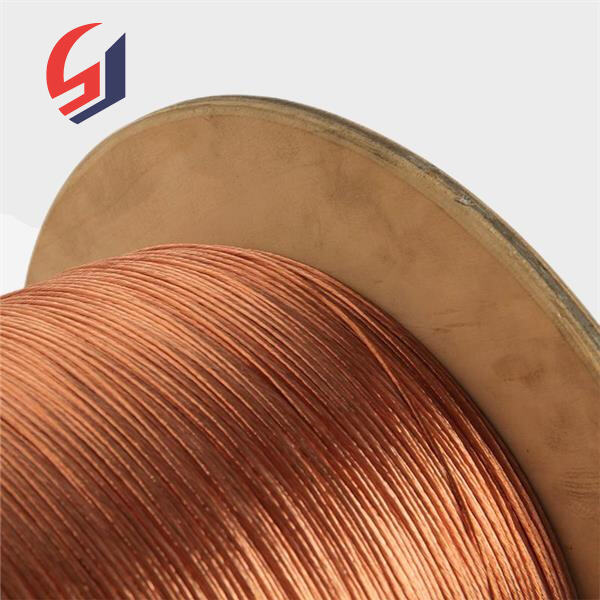

Shenzhou Cable manufactures the high-quality magnet wires that comply with the EN 60317 13 Standards. Our copper is the highest quality available, and the insulation we use is specifically formulated to withstand extremely high heat and electrical stress. We are diligent in our manufacturing process and review our work extensively to ensure that our wires are sturdy, dependable, and top quality.

We, not only, manufacture our regular magnet wires but also, we can develop customized changeable wires that satisfy our customers' demands. The setup includes wires with unique insulation that can withstand even more heat, wires that are purposely designed to have better heat handling, and coatings that can protect them from environmental degradation. We can tailor this to specific criteria in different applications - getting our customers exactly what they are looking for on their projects.

The quality is the main component of enameled wire. The factory goes through numerous levels of quality inspections to ensure that the products are in compliance with the requirements of international standards and customers. (1) Control of raw materials from pure copper, to high quality insulating lacquer, the raw materials are subjected to rigorous screening in order to ensure stable performance. 2.) Whole-process monitoring. From the beginning of wire drawing to the process of enameling, each stage of production is subject to strict tests, including electrical performance as well as the withstand of insulation voltage and tensile tests to ensure reliability. (3) Full certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification, SGS certification to enhance the confidence of customers.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.

The modern production methods and strict quality control procedures in our enameled-wire manufacturing facilities allow us to efficiently deliver our products throughout the world. By working closely with our international logistics partners we can offer customized logistics solutions that meet the specific needs of our customers. Our delivery network in the world covers important ports, ensuring that goods reach their destinations promptly and safely. Sales staff at our company also offer online tracking solutions that keep our customers updated on the status of their shipment and improves transparency in the supply chain.

Our enameled wire factory is able of customizing products to meet customers' special requirements and also provide complete after-sales service. Different specifications: The factory can manufacture enameled wires with a wide range of specifications, including various wire diameters, enamel thicknesses, temperatures and insulation ratings to fit a variety applications.