So, aluminum enameled wire is a crucial component in many electrical devices. This unique type of wire is commonly used for motors, transformers and other electrical equipment where it needs to carry electricity well. Next, let's discuss conductivity, which refers to the ability for electricity to move through a material. Ensuring good conductivity is crucial to ensuring that electrical devices function as well and efficiently as possible.

Good wiring is important; it keeps the electrical devices functioning properly and safely. Poor quality wiring can mean serious problems. Low-quality wiring might give electrical shocks that hurt people, for example. It can also cause fires, which can destroy property and endanger lives. In the worst cases, sloppy wiring could even lead to explosions. These problems are extremely serious, sometimes even deadly. This is why we should always be mindful of the quality of wiring we install.

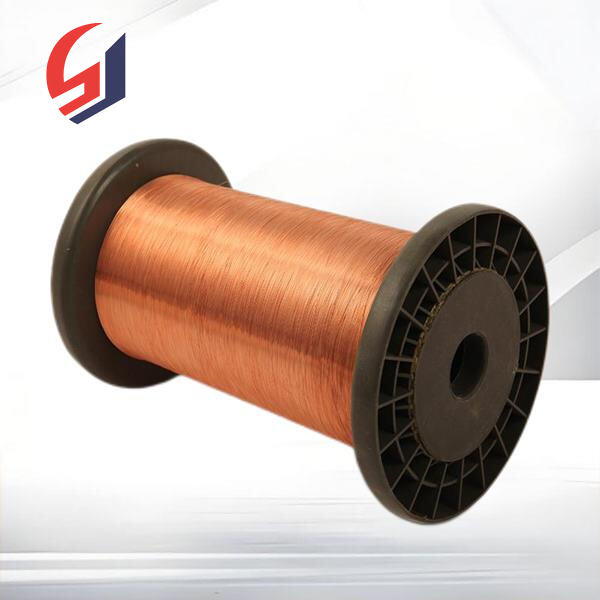

Copper wires have been used for a long time, and many people prefer them because they conduct electricity better than aluminum wires. Copper has a high conductivity ratio, so the electricity can travel through it more readily. Copper wires do not rust easily, which is important because rust can weaken the wire. In addition, copper is easy to handle, which is why electricians prefer it.

Aluminum wire, on the other hand, costs less than copper. This makes it more manageable to install as it is lighter and less rigid. Akro-Mils are very flexible and this can come in handy when you have tight space and need to bend the wire. But aluminum doesn’t conduct electricity as well as copper wire. In addition, aluminum expands and contracts more than copper when the temperatures are out of balance. That can pose an electrical contact and loosening risk over time.

Copper vs aluminum super enamelled aluminium winding wires is a decision during the selection process that requires careful consideration of your requirements as well as your spending plan. The needs can vary depending on the project, and Shenzhou Cable offers copper and aluminum wiring options. In this way, we can make sure we have the right product for which every customer has specific needs.

Gauge: This refers to the thickness of the wire. This is significant because the thicker the wire, the more electricity it can handle without melting. If the wire is too thin for the load of electricity that it carries, it can glow red hot and lead to fire or other dangers. Always check the gauge to ensure it is appropriate for the project you are working on.

For example, the initial investment for high-quality electrical wires may seem a bit too high, but they may save you a lot of money in the future. Poor quality electrical cable is more susceptible to damage and more likely to fail, which means it needs to be replaced more frequently than high quality means. That can incur additional expenses and create lost time.

Our wire factories that are enameled ensure efficient delivery of products globally thanks to advanced production technology and strict quality control. Working closely with our logistics partners in the world We are able create customized logistics solutions to meet the specific needs of our customers. Our global delivery network covers major ports, ensuring that products reach their destinations efficiently and securely. Sales staff at our company also offer online tracking solutions that inform our customers of the status of their shipment, improving supply chain transparency.

Copper wire manufacturers in enamel can produce high-quality products at cheaper prices due to their production capacity on a large scale. 1.) Mass production: The company can quickly respond to large orders, and ensure the timely delivery. (2) Reduced costs through an efficient manufacturing process and optimization of equipment, the factory can reduce waste and increase output rate so that the unit price is reduced and giving customers more competitive cost.

Quality is the key component of enameled copper wire. The factory passes through many stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Raw material control: from high purity copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure their stability. 2.) Monitoring throughout the process. From the beginning of wire drawing to enameling, each step of production is subject to rigorous testing such as electrical performance as well as the withstand of insulation voltage and tensile tests to ensure the reliability. To increase the confidence of customers manufacturing facilities that are of high quality are usually certified with ISO 9001 for their quality management system and UL safety certification.

Our factory can customize products to satisfy the demands of customers and provide comprehensive support following sales. Different specifications: The factory can manufacture enameled wires in a wide range of specifications, including different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of situations.