While most wires are round, Coil Flat Wire is specifically designed to be flat. That flat form makes it highly useful in areas like factories, where, as a rule, there’s not that a lot of spare house. One reason industries prefer to utilize it is that its flexible nature allows it to be coiled tight; therefore, it takes up less space than round wire.

Shenzhou Cable is one such company manufacturing Coil Flat Wire. So they can keep helping a lot of businesses and produce this wire. This wire comes in our Coil Flat Wire and is incredibly strong and durable, which is critical in factories where wires are susceptible to damage. It does not break or bend easily; therefore, it is most suitable for placing in machines and tools that will have to do a lot of work without failure.

Coil Flat Wire has a very good ability to conduct a lot of electricity. That allows it to transport power over vast distances without losing a lot of energy on the way. Factories loves this feature because it helps them to save on their electricity bills. By using less electricity, they can then invest that money in the things they care about most in their business.

Conductors offered by Shenzhou Cable: Coil Flat Wire with wire of very strong and flexible nature. This means it can easily bend into tight spaces without breaking. This allows for that extra flexibility when it comes to installing electrical wiring, which often has to maneuver around pipes, beams and other obstacles. This wood makes the work easier and faster, the wire can around these obsticals without any issue.

Coil Flat Wire is an integrity based manufacturing industry. It finds use in various machines like conveyor belts, motors and generators. These machines are critical for producing goods and keeping factories operating efficiently. Coil Flat Wire common usage in machine because of its strength and durability against wear and tear.

Coil Flat Wire is not just durable, but also power capable. This skill allows machines to perform well without wasting power. It's also used in automation systems that are increasingly widespread in factories. These systems use advanced devices and sensors to help control the manufacturing process. Coil Flat Wire is an essential component of these systems, ensuring that everything functions as it should.

A possible downside of using Coil Flat Wire, however, is that it is often a more costly option than their round wire counterparts. This is because it needs to be manufactured in certain processes which make the flat shape. Nonetheless, even if they might be pricier from the outset, the advantages of using Coil Flat Wire in the long run, such as its longevity and capacity to manage substantial power loads, frequently surpass the initial investment.

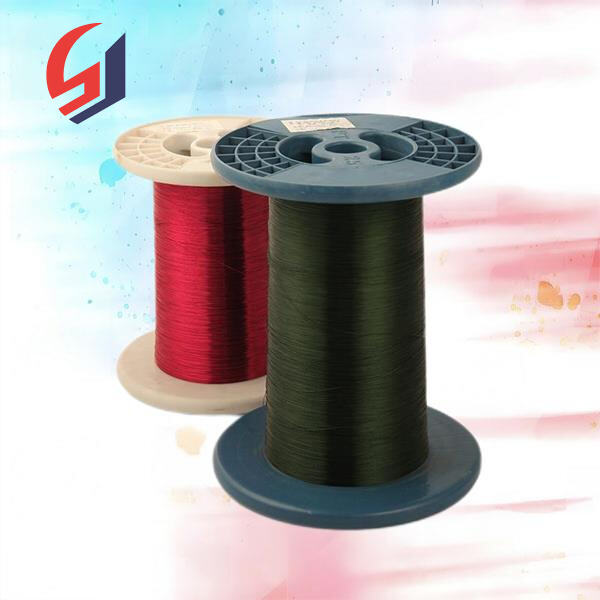

Our enameled wire factory is able to customize products according to customers' special requirements and also provide full after-sales support. Different specifications: Our factory can manufacture enameled cables with numerous specifications that include wire sizes, thicknesses of the enamel, temperature ratings, and insulation ratings.

The high-quality of enameled wire copper is of paramount importance. The factory goes through numerous stages of quality inspection to ensure that the products are in compliance with international standards as well as customer demands. (1) Control of raw materials From pure copper to high quality insulation varnish, the raw materials are rigorously screened to ensure their stability. (2) Whole-process monitoring: From drawing wires to enameling each stage of production goes through rigorous testing, such as tensile strength as well as electrical performance and voltage withstand tests, to guarantee the product's reliability. (3) Complete certification: Quality factories usually have the ability to pass ISO 9001 quality management system certification as well as UL safety certification. SGS certification to increase the trust of the customer.

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.

Our wire factories that are enameled ensure efficient delivery of products globally thanks to advanced production technology and strict quality control. Working closely with our logistics partners in the world We are able create customized logistics solutions to meet the specific needs of our customers. Our global delivery network covers major ports, ensuring that products reach their destinations efficiently and securely. Sales staff at our company also offer online tracking solutions that inform our customers of the status of their shipment, improving supply chain transparency.