Bare copper price very important for those work wire and electrical equipment. If you have ever come across a wire with no covering over it, then you have seen bare copper wire. It is one of the important types of wire that is widely used in many electric systems. Now, we will discuss the way that bare coppers fluctuate over time, the key driver of that price up and down, the economic implications of rising prices, the influence of global demand, and how one attempts to forecast the future price of copper. Now let's start and dive into these fascinating subjects!

Bares copper prices fluctuate in nature, so they are never constant. Like everything we purchase, the commodity price of raw copper is based on supply and demand — how much copper people want to buy and how much they’re willing to pay for it. At other times (and again, with some exceptions), there aren't that many people who want bare copper. When greater numbers want to purchase it the price typically rises. That is due to the sellers realizing that they have the ability to demand a higher price when demand is high. Conversely, the price drops when fewer people want to buy it. If there is not much interest, sellers may drop the price to lure more buyers.

The cost of bare copper can be influenced by multiple factors. One major factor is supply and demand. Supply is the amount of copper that is out there; demand is the amount people want to buy. If there is a lot of demand for bare copper, prices go up because there isn’t a lot of copper to go around. It makes the price higher due to the limited supply. One more thing that has an impact in price for bare copper is the manufacturing cost of it. Costs of copper can vary depending on where the copper is located. Therefore, some regions may have a lower cost per unit of copper than others. Mining methods may also influence the price of copper. Government taxes and regulations also can alter the cost of the copper. Finally, fluctuations in currency value will also have an effect on copper prices, thereby making them more or less expensive as well.

Get ready for some nuggets: When copper prices — or the price of copper to the trade, or the price of junk level or higher manufacturers — rise, the economy seriously marches. For instance, if the price of copper increases, then the cost of producing and shipping products with copper wires and other electrical equipment is higher. This can result in higher prices for consumers, potentially meaning they will purchase fewer of these products. “If consumers believe prices are excessively high, they may elect to delay or seek lower-price alternatives. Moreover, businesses that rely heavily on copper may be forced to look for substitute materials to curb their expenses. This can alter the quality and performance of their products when they switch to other materials. This means that increased copper prices can impact not only individual consumers but businesses and the broader economy as a whole.

Global Demand: End users (manufacturers) have cut copper purchases through the end of the year. They view prices as too high and anticipate a recession. Manufacturers that rely on copper have reduced production significantly. As a result, copper may be headed for the biggest annual drop in demand in over 60 years.

The demand for bare copper is highly sensitive to global events. What this means is that the price of copper is quite variable depending on which countries are the buyers and which countries the producers. So for example, if a country has lots of factories and its economy is good, it will need more copper to make more products. This may increase the consumption of bare copper. When demand rises but the supply remains unchanged, the amount of copper available diminishes, and the price can rise. "Countries producing copper won't be able to keep pace and prices will increase," he said. For anyone who buys or sells copper, understanding these things and how global events and economic conditions can impact copper demand is helpful.

However, determining future copper prices can be a difficult task. Demand, production costs, rules and the global economy are just a few of the factors that will need to be considered. But to make predictions about what happens next, we can look at past prices. Analyzing the deviations between old trends and current market conditions would allow experts to inform businesses on whether and how to use copper. Such forecasts would be helpful for organizations to strategize, plan, and allocate resources effectively.

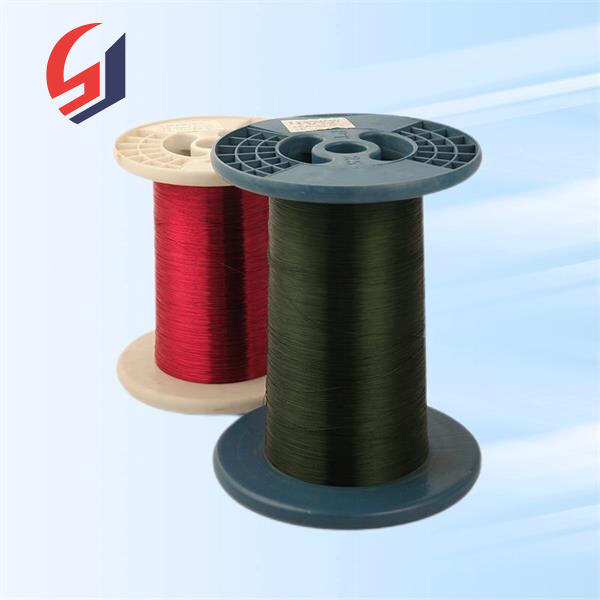

Our factory can customize products to satisfy the demands of customers and provide comprehensive support following sales. Different specifications: The factory can manufacture enameled wires in a wide range of specifications, including different wire diameters, enamel thicknesses, temperatures, and insulation ratings to meet a variety of situations.

Copper wire manufacturers in enamel are able to produce top-quality products for a lower price due to their capacity to produce large quantities. 1.) Mass production: The manufacturing facility can quickly respond to large orders and ensure prompt delivery. (2) Cost reduction. By optimizing the production process as well as equipment it is in a position to cut down on production, reduce waste, and reduce unit costs and allow customers to be more competitive in their prices.

The latest production techniques and rigorous quality controls in our enameled-wire manufacturing facilities allow us to efficiently deliver our products all over the world. Through close collaboration with our logistics partners in the world we are able to create customized logistics solutions to fulfill the specific requirements of different clients. Our global delivery network includes major ports, ensuring that products reach their destinations quickly and safely. Additionally our sales representatives provide online tracking to keep customers informed of the status of their deliveries in real time, enhancing supply chain transparency and customer satisfaction.

The high-quality of enameled wire copper is essential. The factory goes through numerous quality checks to make sure the products are up to international standards and meet customer demands. (1) Raw materials control from pure copper to top quality insulating lacquer, raw materials are screened thoroughly for stability. (2) Monitoring of the whole process From wire drawing to the process of enameling each stage of production is subjected to rigorous tests including tensile strength along with electrical and insulation voltage withstand tests, in order to assure the reliability of the product. (3) Full certification The majority of quality factories get ISO 9001 quality management system certification, as well as UL safety certification. SGS certification, to boost customer confidence.