Hello! Ever wonder why the price goes up and down for 7/16 copper wire? This can be a little confusing, but there are good reasons for these changes. This article will discuss the reasons behind copper wire 7/16 pricing fluctuation, as well as the factors you should consider before purchasing it. Knowing these reasons can help you choose copper wire better when buying copper wire.

There are many reasons the price of 7/16 copper wire can vary. A major reason is the amount of copper available and the amount people want to buy. That’s what we refer to as supply and demand. “But when more people want copper — say, to build or make electronics — that should push the price up.” But if fewer people want it, then the price may go down. It’s like when there are so many kids that want one toy, the price can be higher if it’s hot!

A third key factor in the price is the copper's place of origin. Copper is a mineral that is mined from the earth. Further, if there are issues getting the copper from the source, i.e., if it is becoming harder to mine it, or there are problems in the countries where it exists, the cost of copper & 7/16 copper wire might rise. If, for example, a mine has to close for safety reasons, there will be less copper mined, so the price will climb.

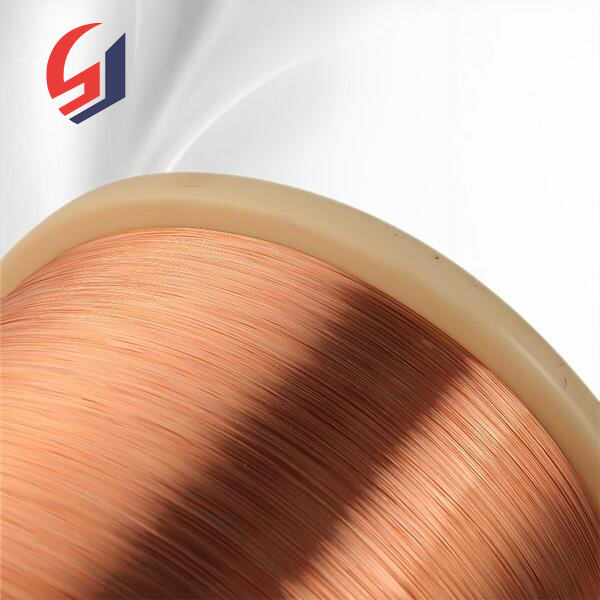

Purchasing 7/16 copper wire will include more factors that you need to take into consideration if you join the wire before to a good deal. Another big factor to consider is the quality of the wire. High quality copper wire is very vital as it can last for many years and avoid otherwise minor electrical problems. At Shenzhou Cable, we prioritize offering top-quality copper wire to our clients, and that's why we do what we do.

The company from which you purchase may also determine what you get for your money. The first step to take is to find a reliable company like Shenzhou Cable that has market competitive prices and ship on time. Consider sourcing copper wire directly from the manufacturer as well. This might save you money since you are not paying additional costs from middlemen, distributors, or retailers.

It’s worth noting that the prices of 7/16 copper wire can fluctuate due to different factors when prognosticating the future costs. This is mainly because different industries consume large amounts of copper for various developments including infrastructure, electronics, and transportation. And as these industries expand over the years, they will only use more copper wire; this should push prices higher.

The price of copper is also influenced by the global economy. Economic uncertainty, changes to trade rules, and even natural disasters can play a part in driving up the price of copper and, thus, 7/16 copper wire. For instance, if a natural disaster strikes in a nation where copper is mined, it may become more difficult to obtain copper, potentially driving up prices.

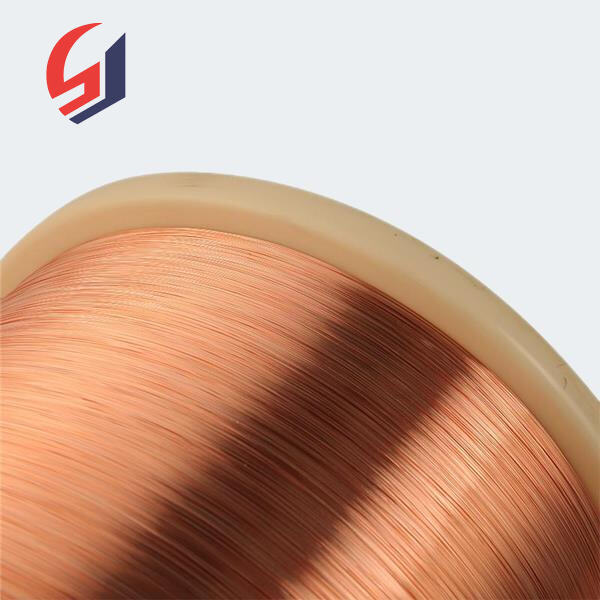

Copper wire factories that are enamel can produce high-quality products at cheaper prices due to their scale production capability. (1) Mass production: The factory is able to react quickly to the demands of large orders and at the same time ensure that the delivery time is on time. (2) Cost reduction through a more efficient production and optimizing equipment factories can cut down on consumption and increase the rate of output, thus reducing unit cost and giving customers more competitive cost.

Our enameled wire factory is able of customizing products to meet customers' particular requirements. They also provide complete after-sales service. Diversified specifications: The factory is able to produce enameled wires that meet a broad variety of specifications, which include various wire diameters, enamel thicknesses, temperature ratings, and insulation ratings to fit a variety different applications.

The high-quality of enameled copper is of paramount importance. The manufacturing facility goes through a variety of quality control procedures to ensure that the product meets standards of international quality and meet the customer's requirements. (1) Control of raw materials from pure copper to premium insulating lacquer, the raw products undergo rigorous screening to ensure their performance is stable. 2.) Whole-process monitoring. From wire drawing to enameling, every stage of production is subjected strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure quality and safety. In order to increase customer confidence, quality factories are usually certified by ISO 9001 for their quality management system and UL Safety certification.

Modern production technology and strict quality control procedures in our enameled-wire manufacturing facilities allow us to provide products with speed across the globe. In collaboration with our logistics partners in the world we are able to offer customized logistics solutions that meet the specific needs of our customers. Our global network of delivery partners includes important ports to ensure that the products reach their destinations quickly and safely. Our sales team also offers online tracking solutions that keep our customers up-to-date on the status of their shipment and improves transparency in the supply chain.