Copper is an essential metal that is required to manufacture many of the products we use in our daily lives. Copper wires are some of the commonest things made from copper. These practice wires are present all over the place; within houses, buildings, and cars as well. These are vital since they assist by transferring electricity from one location to another, enabling us to utilize lights, appliances, and other electrical devices.

The market is one of the main reasons why the price of copper wires changes often. This is the market, a large store where buying and selling takes place. When more people want copper than there is to be had, the price increases. The reason is simple: supply and demand; when there is a high demand for something but the supply is low, the value of that item increases. But if lots and lots of copper is produced and few people want to buy it, then the price goes down. This is due to sellers wishing to draw in buyers.

There are many different things that can change the market. For example, copper used that is to be sold as new copper will become a regulated commodity. Natural disasters like floods or earthquakes can further impact copper scarcity. Politics and government decisions can cause market changes, too. These difficulties can make it difficult for people to estimate how much copper wires cost and how much they tend to pay in the future.

Copper is the reason behind yet another reason why copper wires cost a lot, copper theft. Unfortunately, many individuals take copper wires from construction sites, electrical stations, and even people’s homes. This stealing is a lot of trouble, because it makes more copper wires cost for all, “When wires are being taken, people aren’t just making the wires, but making sure they get where they need to go.

The theft of copper wires also can damage systems that provide electricity to homes and businesses. This can cause power outages, during which people may not have electricity for a period of time. In some worst case scenarios, it can actually start fires as well, which can lead to disaster. Why copper theft is a game not only for the person whose wires are stolen, but for the entire community.

Another cost-cutting method is to consider using different types of wires. Copper wires are, therefore, the most common, but there are other wires, such as aluminum wires. Aluminum wires might make a good choice because, while they may not conduct electricity as well as copper wires, they can still do well for many different tasks and tend to be cheaper. This can make a great option for individuals who really need to save.

The trend of high copper wires prices is expected to continue for some time, according to experts. And this is happening not only because more people want copper but because there are a number of problems securing enough copper from around the globe. COVID-19 pandemic also made it more difficult to provide the required copper wires. Those challenges mean that prices aren’t likely to come down any time soon.

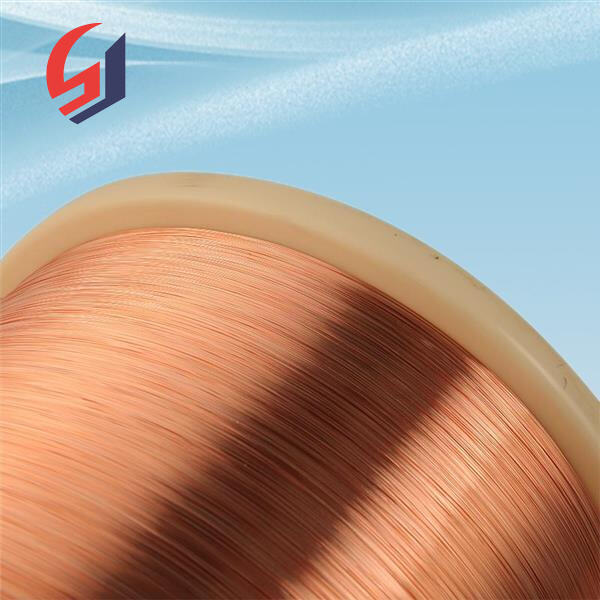

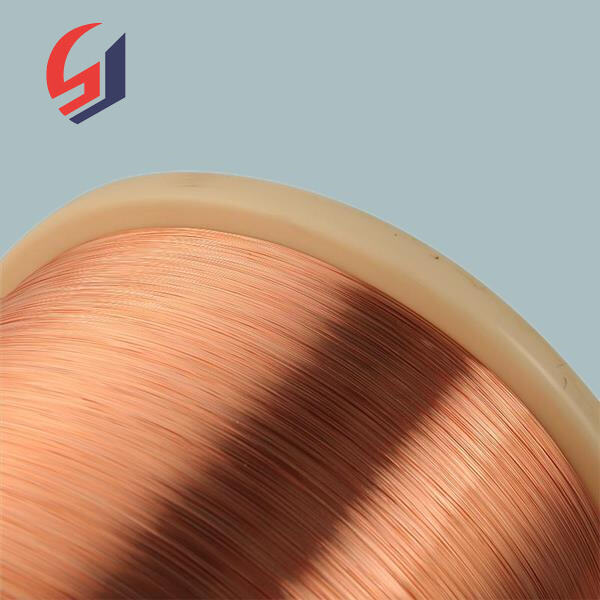

Enamel copper wire factories can make high-quality products at an affordable cost because of their production capacity on a large scale. 1.) Production in mass: The manufacturing facility can quickly respond to large orders, and ensure timely delivery. (2) Cost reduction. By improving the process of production and equipment factories are capable of reducing the amount of waste produced, boost output, and cut down on unit expenses and allow customers to get a better price.

The quality of enameled copper is of paramount importance. The factory goes through numerous quality inspection stages to ensure the products are up to standards set by international standards and satisfy customer requirements. (1) Control of raw material Starting from pure copper through to top quality insulation varnish, the raw materials are thoroughly screened to ensure stability. 2) Whole-process monitoring. From wire drawing through to enameling, every stage of production goes through strict tests, including electrical performance, insulation voltage withstand, and tensile tests in order to ensure high-quality and reliability. To improve the trust of customers, quality factories are usually certified with ISO 9001 for their quality management system as well as UL safety certification.

The modern production methods and stringent quality control in our enameled-wire factories enable us to ship products quickly across the globe. We work closely with international logistics partners in order to develop customized logistics solutions to meet the demands of our customers. Our global delivery network covers major ports, ensuring that your products get to their destination quickly and in a safe manner. Additionally our sales personnel provide online tracking to keep customers informed about the status of their deliveries in real time, enhancing the transparency of supply chains and satisfaction with our customers.

Our enameled wire factory can customize the products according to customers' special requirements and also provide an extensive after-sales assistance. Diversified specifications: Our factory can produce enameled cables in a variety of specifications including wire diameters, thicknesses of enamel, temperature ratings, and insulation ratings.