Le moteur Saturn V Le moteur Saturn V est un moteur de fusée extrêmement puissant. Il a été utilisé par la NASA sur la fusée Saturn V, développée dans les années 1960 et 1970. Cette fusée a été un élément clé pour envoyer des astronautes sur la Lune lors des missions historiques Apollo. Qu'est-ce qu'un moteur Saturn V et à quel point cela a-t-il été important ? Il a également permis à la fusée de pivoter et d'accélérer pendant le vol, ce qui était crucial pour atteindre la Lune avec succès.

Lorsque la NASA souhaitait envoyer des astronautes sur la Lune, elle devait construire une fusée assez puissante pour les y amener. Le moteur Saturn V est devenu leur choix privilégié pour réaliser cet objectif. Cher, parfait fil en aluminium émaillé moteur de fusée : souviens-toi de tous ces brillants scientifiques et ingénieurs qui ont travaillé DUR pour te concevoir et te construire ? Il fallait qu'il soit assez puissant pour faire décoller la grande fusée du sol et l'envoyer dans le ciel. Quelle démonstration incroyable de travail d'équipe et d'effort pour créer le moteur Saturn V.

Non seulement le moteur Saturn V est massif, mais il est également extrêmement puissant. Il mesure presque deux mètres de haut et pèse près de cinq tonnes, aussi lourd qu'une petite voiture. Le moteur comprend de nombreux composants distincts tels que des pompes, des vannes et des chambres. Toutes les pièces du moteur sont importantes pour qu'il fonctionne correctement. Il fonctionne avec un carburant spécial appelé hydrogène liquide, qui brûle lorsque le moteur est allumé. Ce carburant produit une flamme extrêmement chaude et puissante qui s'échappe de la base du moteur. C'est donc cette grande flamme qui pousse la fusée vers l'espace, permettant ainsi à la fusée de décoller du sol et d'échapper à l'attraction terrestre.

Le moteur Saturn V était incroyable car il a permis à la NASA signification du câble cca pour accomplir des choses auparavant impossibles. De cette manière, il pouvait même décoller du sol avec une charge lourde. Cela n'est possible que parce que le moteur utilisait un carburant hautement énergétique et intégrait de nombreux composants parfaitement interagissants. De plus, le moteur Saturn V jouait également un rôle dans la capacité du fusée à manœuvrer vers le haut, le bas et les côtés une fois dans l'espace, ce qui était essentiel pour que les astronautes atterrissent avec succès sur la Lune. C'était le moteur essentiel qui a rendu les missions vers la Lune dorée possibles.

Le moteur Saturn V a changé la manière dont la NASA menait l'exploration spatiale. Ils ont pu envoyer des humains sur la Lune, un exploit considérable pour la science ainsi que pour l'humanité. C'était une mission qui a ouvert une toute nouvelle ère de possibilités d'exploration au-delà de la Terre. La NASA pouvait également acquérir des connaissances sur l'espace et son fonctionnement grâce au moteur Saturn V. Le cCA vs cuivre pur lancer des astronautes, des satellites et d'autres instruments dans l'espace pour en apprendre davantage sur toutes sortes de choses dans notre univers. Ici, le moteur Saturn V a permis toutes ces explorations humoristiques.

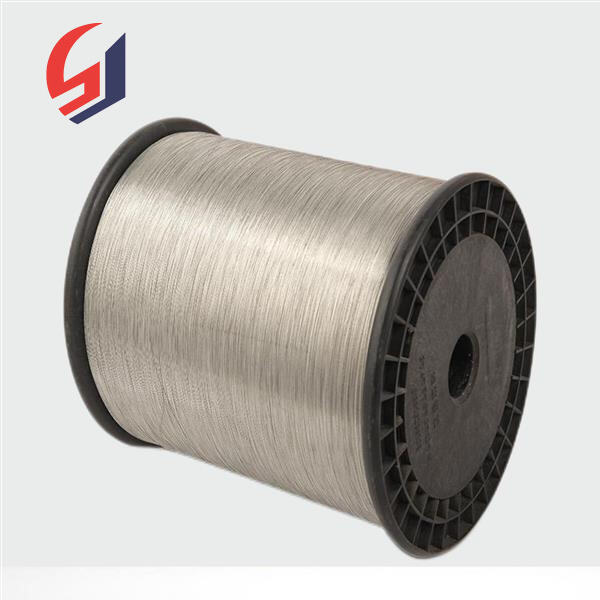

Nos usines de fils avec des fils émaillés assurent une distribution efficace des produits à l'échelle mondiale grâce à une technologie de production avancée et à un contrôle qualité rigoureux. Nous collaborons avec nos partenaires logistiques internationaux pour créer des solutions logistiques personnalisées qui répondent aux besoins de nos clients. Notre réseau mondial de livraison couvre les ports importants, garantissant que vos produits arrivent à destination rapidement et en toute sécurité. Le personnel des ventes de notre entreprise propose également des solutions de suivi en ligne qui informent nos clients sur l'état de leurs expéditions et améliorent la transparence dans la chaîne d'approvisionnement.

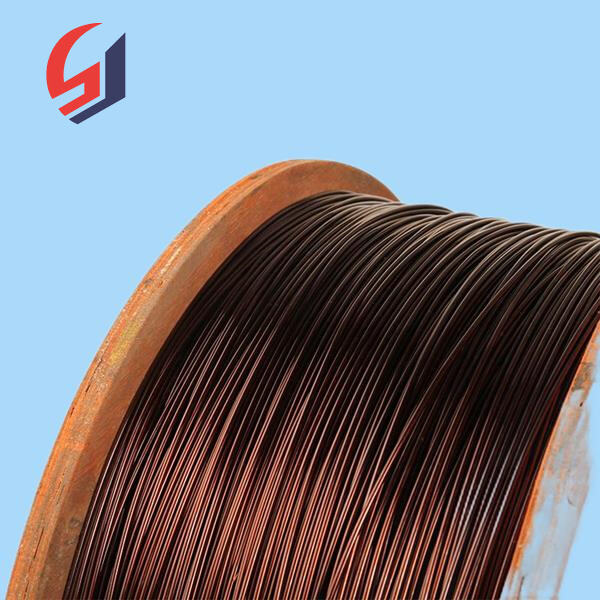

Les fabricants de fils en cuivre avec revêtement d'émail peuvent produire des produits de haute qualité à des prix plus bas grâce à leur capacité de production à grande échelle. 1.) Production de masse : L'entreprise peut répondre rapidement aux grandes commandes et garantir la livraison à temps. (2) Réduction des coûts grâce à un processus de fabrication efficace et à l'optimisation des équipements, l'usine peut réduire les déchets et augmenter le taux de production afin que le prix unitaire soit abaissé et offrir aux clients un coût plus compétitif.

La haute qualité du fil en cuivre émaillé est d'une importance capitale. L'usine de fabrication passe par une variété de contrôles qualité pour s'assurer que la qualité des produits est conforme aux normes internationales et satisfait les besoins des clients. (1) Contrôle des matières premières : Du cuivre pur à la laque d'isolation de haute qualité, toutes les matières premières subissent un filtrage strict pour garantir une performance stable. (2) Surveillance continue du processus : De l'étirage du fil à l'émaillage, chaque étape de production passe par des tests rigoureux, y compris la résistance à la traction ainsi que des tests électriques et de résistance à la tension d'isolation, pour assurer la qualité du produit. Pour renforcer la confiance des clients, les usines de qualité sont généralement certifiées ISO 9001 pour leur système de management de la qualité, ainsi que certifiées UL pour la sécurité.

Notre usine de fils émaillés est capable de personnaliser des produits pour répondre aux exigences spéciales des clients et offre également un service après-vente complet. Différentes spécifications : L'usine peut fabriquer des fils émaillés avec une large gamme de spécifications, y compris divers diamètres de fil, épaisseurs d'émail, températures et classements d'isolation pour s'adapter à de nombreuses applications.